UV vs. IR Grade Fused Silica

Apr. 01, 2025

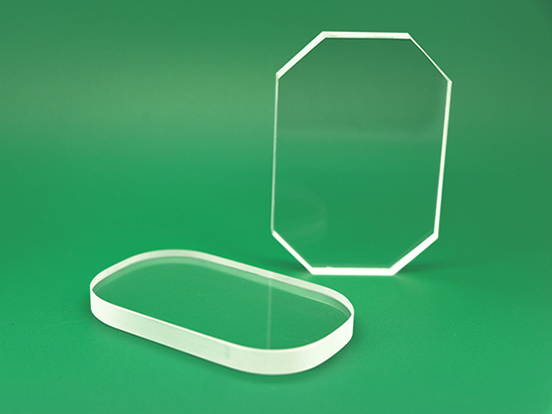

Fused silica is a common glass type used in the optics industry to manufacture optical components such as lenses, windows, mirrors, prisms, and beamsplitters. Fused silica is often a preferred material for precision optics due to its consistent and repeatable optical performance. Fused silica is renowned for its exceptional thermal stability, attributed to its low coefficient of thermal expansion. This property enables it to withstand rapid temperature fluctuations without cracking, making it ideal for applications requiring high durability under varying thermal conditions. Additionally, fused silica exhibits high chemical resistance and minimal fluorescence, further enhancing its suitability for demanding environments.

Among the various types of fused silica, UV-grade and IR-grade are the most commonly utilized, each optimized for specific spectral regions.

IR grade fused silica differs from UV grade fused silica by its reduced amount of OH- ions, resulting in higher transmission throughout the NIR spectrum and reduction of transmission in the UV spectrum.

Introduction to UV and IR Grade Fused Silica

Fused silica, a form of glass made from high-purity silica, possesses remarkable optical properties, making it highly desirable in various industries. UV and IR grade fused silica are specifically engineered to excel in different regions of the electromagnetic spectrum, catering to distinct applications due to their tailored transmission characteristics.

UV Grade Fused Silica

UV-grade fused silica is synthetically produced through the flame hydrolysis of high-purity silicon compounds. This manufacturing process results in a material with excellent transmission in the ultraviolet (UV) spectrum, typically ranging from 185 to 2100 nanometers. However, the presence of hydroxyl (OH⁻) ion impurities introduces absorption bands around 1.4 µm, 2.2 µm, and 2.7 µm, which can limit its effectiveness in certain near-infrared (NIR) applications.

UV grade fused silica is meticulously crafted to exhibit exceptional transmission capabilities within the ultraviolet spectrum, spanning wavelengths from 185 to 2100 nanometers. Its formulation involves stringent purification processes to minimize impurities that can impede UV transmission. UV grade fused silica is widely renowned for its:

- High transmission efficiency in the UV range.

- Low absorption and minimal fluorescence in UV light.

- Consistency in optical properties across the UV spectrum.

IR Grade Fused Silica

In contrast, IR-grade fused silica is engineered to have a significantly reduced concentration of OH⁻ ions, achieved by melting high-quality quartz or employing specialized manufacturing techniques. This reduction enhances its transmission capabilities in the NIR spectrum, typically spanning wavelengths from 780 to 3500 nanometers, while diminishing its performance in the UV range. The lower OH⁻ content minimizes absorption in the NIR region, making IR-grade fused silica particularly suitable for applications involving infrared optics

- Superior transmission in the infrared region.

- Reduced absorption and minimal thermal effects in the IR range.

- Consistent optical performance across the infrared spectrum.

Applications Around 2 µm Wavelength

The advancement of laser technologies operating around the 2 µm wavelength, such as thulium (2080 nm) and holmium (2100 nm) lasers, has expanded the applications in this spectral region. Given that 2 µm is near one of the OH⁻ absorption peaks in UV-grade fused silica, using this material can lead to significant absorption, resulting in heat generation and potential damage to optical components. Therefore, IR-grade fused silica, with its reduced OH⁻ content, is a more suitable choice for such applications, despite its higher cost and lower availability.

Characteristics and Properties

UV Grade Fused Silica Properties

UV grade fused silica exhibits exceptional characteristics tailored for applications requiring precise UV transmission:

- High UV Transmittance: It boasts high transmission efficiency in the UV spectrum, ensuring minimal loss of UV light passing through the material.

- Low Absorption: UV grade fused silica minimizes absorption of UV light, allowing for accurate analysis and experimentation in UV-sensitive applications.

- Minimal Fluorescence: Its low fluorescence properties prevent unwanted emission of light when exposed to UV radiation, ensuring accuracy in measurements and analyses.

IR Grade Fused Silica Properties

IR grade fused silica possesses distinctive properties suited for efficient infrared transmission:

- Superior IR Transmittance: It demonstrates superior transmission capabilities in the infrared spectrum, enabling effective passage of IR light through the material.

- Reduced Absorption: IR grade fused silica minimizes absorption of infrared light, facilitating precise analysis and imaging in IR-sensitive applications.

- Thermal Stability: It exhibits good thermal stability, allowing it to withstand higher temperatures associated with certain IR applications without significant degradation.

Applications

UV Grade Fused Silica Applications

UV grade fused silica finds widespread application in various fields that require precise UV transmission:

- UV Spectroscopy: It is extensively used in UV spectrometers for analyzing substances based on their UV absorption and emission spectra.

- Semiconductor Manufacturing: UV grade fused silica is crucial in photolithography processes for precise patterning in semiconductor manufacturing.

- Medical Instrumentation: It is employed in medical equipment such as UV sterilization systems and diagnostic tools reliant on UV light.

IR Grade Fused Silica Applications

IR grade fused silica is employed in numerous applications requiring efficient transmission within the infrared spectrum:

- Infrared Spectroscopy: It is vital in spectroscopy instruments for analyzing materials based on their IR absorption spectra.

- Thermal Imaging: IR grade fused silica optics are used in thermal imaging devices for accurate temperature measurements and imaging.

- Laser Systems: It serves as a fundamental component in infrared laser systems for applications in telecommunications, material processing, and defense.

Conclusion

In summary, selecting the appropriate grade of fused silica—UV or IR—depends on the specific wavelength requirements of the application, balancing factors such as transmission efficiency, thermal stability, and material availability.

In conclusion, the distinction between UV and IR grade fused silica lies in their optimized transmission properties within different segments of the electromagnetic spectrum. UV grade fused silica excels in the ultraviolet range, while IR grade fused silica demonstrates superiority in the infrared spectrum.

Understanding these distinctions is pivotal for selecting the most appropriate grade of fused silica tailored to specific optical requirements. The precise engineering and properties of UV and IR grade fused silica underscore their indispensability in advancing technology across various industries.