Plano-Concave Lenses Maintenance and Cleaning Tips

Oct. 10, 2025

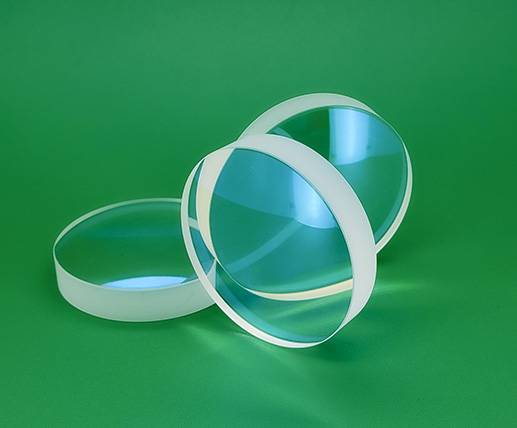

Maintaining high optical performance is crucial for every precision component in an optical system — and plano-concave lenses are no exception. Whether they are used in laser optics, imaging equipment, or research instruments, proper cleaning and maintenance directly determine the stability, accuracy, and lifespan of these lenses.

At CLZ Precision Optics, we understand how even the smallest particle or scratch can affect optical performance. That’s why our experts recommend following professional maintenance procedures to keep your plano-concave lenses in pristine condition.

Why Proper Maintenance Matters

Plano-concave lenses feature one flat surface and one concave surface designed to diverge light. Due to their negative focal length and curved geometry, these lenses are particularly sensitive to:

Dust and surface contamination

Fingerprints, oils, and chemical residues

Improper handling that causes scratches or coating damage

Even minor contamination can scatter light or reduce transmission efficiency. Regular cleaning not only restores clarity but also prevents irreversible coating degradation caused by moisture or chemical exposure.

Recommended Cleaning Environment

To ensure cleaning effectiveness, the working environment is as important as the process itself. CLZ Precision Optics recommends cleaning plano-concave lenses in:

A cleanroom or dust-free workspace (ISO 7 or higher)

Low humidity conditions to prevent static and moisture buildup

Soft, diffused lighting for clear inspection of contaminants

Always wear powder-free nitrile gloves and use anti-static tools when handling precision optics.

Proper Handling Techniques

Before cleaning, it’s essential to handle the lens correctly to avoid mechanical or coating damage:

Always hold the lens by its edges, never touch the optical surfaces.

Place lenses on soft, lint-free optical tissue when not in use.

Avoid stacking lenses — store them in individual holders or lens trays.

Use plastic-tipped tweezers or vacuum pickup tools for delicate handling.

This ensures the surface coatings and curvature remain intact during cleaning or inspection.

Step-by-Step Cleaning Procedure

Step 1: Air Blow to Remove Dust

Use a filtered air blower or nitrogen spray to remove loose dust particles. Never use your breath — moisture and microscopic particles can deposit on the lens.

Step 2: Inspection Under Light

Examine the lens under a bright, diffused light. Rotate it slightly to detect smudges, fingerprints, or surface residues that need removal.

Step 3: Solvent Cleaning

For oil or fingerprint removal:

Use reagent-grade solvents such as isopropyl alcohol (IPA) or acetone.

Apply the solvent on a lint-free optical tissue or microfiber swab, not directly onto the lens.

Gently drag the tissue in a single motion across the surface — avoid circular rubbing.

For concave surfaces, use cotton-tipped swabs dipped in solvent and move from the center outward.

Step 4: Drying

Allow the lens to air-dry or gently blow-dry it using filtered nitrogen. Avoid heating or rubbing, which can cause coating delamination.

Step 5: Final Inspection

Under illumination, check for any remaining stains or streaks. If necessary, repeat the process using fresh optical tissues and clean solvents.

Coating-Specific Maintenance Advice

Most plano-concave lenses are coated with anti-reflective (AR) coatings to minimize reflection losses. These coatings require additional care:

Avoid using strong alkaline or acidic cleaners.

Do not use ultrasonic cleaning unless verified safe for the coating type.

Always store coated lenses in dry, neutral pH environments.

Avoid touching or wiping coatings excessively, as this may cause micro-abrasions that degrade optical transmission.

CLZ Precision Optics applies durable multi-layer AR coatings, but consistent maintenance is key to preserving their lifetime performance.

Storage and Long-Term Protection

To prevent degradation during storage or transportation:

Store lenses in anti-static, cushioned containers.

Maintain relative humidity below 50%.

Keep away from direct sunlight, heat, and corrosive gases.

For long-term storage, include desiccant packs and sealed containers.

Label each container clearly to prevent handling confusion and accidental contact with optical surfaces.

Signs That a Lens Needs Replacement

Despite regular maintenance, some plano-concave lenses eventually require replacement.

Common indicators include:

Persistent haze or coating discoloration

Deep scratches or chips on either surface

Transmission loss even after thorough cleaning

Visible cracks or stress marks under polarized light

When such damage occurs, performance accuracy and laser safety may be compromised. CLZ Precision Optics offers custom replacement lenses manufactured to match your original optical design or upgraded specifications.

Professional Support from CLZ Precision Optics

At CLZ Precision Optics, we provide more than precision manufacturing — we also help customers extend the service life of their optical components through expert guidance and quality assurance.

Our services include:

Custom plano-concave lens design and production

AR coating optimization for UV, VIS, and IR wavelengths

Optical cleaning consultation and after-sales support

OEM and ODM lens replacement programs

Every lens undergoes thorough inspection and quality certification before shipping, ensuring the highest optical integrity for your system.

Conclusion

Proper cleaning and maintenance are vital for the reliability and performance of plano-concave lenses.

By following correct handling techniques, using approved solvents, and maintaining a clean environment, users can significantly extend lens lifespan while maintaining superior optical performance.

CLZ Precision Optics remains dedicated to providing not only world-class optical products but also practical technical support for global customers who rely on precision optics every day.