Custom Plano-Concave Lenses: What Specifications Matter Most

Oct. 10, 2025

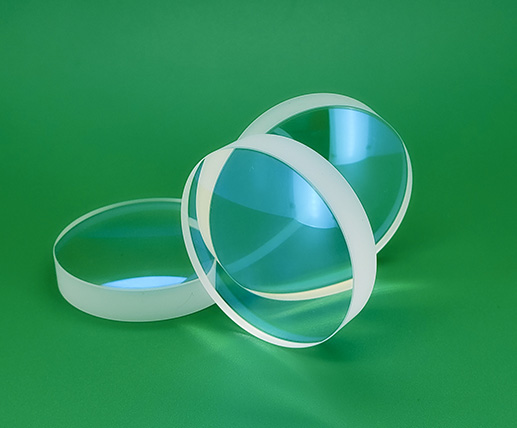

In the field of high-precision optics, custom plano-concave lenses are essential components for controlling light divergence, beam expansion, and optical correction. At CLZ Precision Optics, we specialize in designing and manufacturing plano-concave lenses tailored to meet the exact optical and mechanical requirements of global customers across industrial, medical, and research applications.

Understanding the Function of Plano-Concave Lenses

A plano-concave lens features one flat surface and one inwardly curved surface. This structure causes parallel light rays to diverge after transmission, forming a negative focal length. Such lenses are often used for:

Expanding laser beams

Correcting spherical aberrations

Adjusting focal points in imaging systems

Creating collimated light paths in optical setups

Custom design ensures each lens delivers precise beam control and optical efficiency according to the customer’s system requirements.

Critical Specifications That Define Performance

When customizing plano-concave lenses, every optical specification influences final performance. Understanding these parameters helps procurement specialists and engineers achieve superior optical results.

a. Radius of Curvature (ROC)

The ROC determines the lens’s focal length and beam divergence. A smaller ROC increases divergence, while a larger ROC produces gentler spreading. CLZ Precision Optics can precisely control ROC values to match target focal lengths from –10 mm to –1000 mm.

b. Diameter and Thickness

The mechanical dimensions must align with the optical assembly.

We provide lenses from 6 mm to 150 mm in diameter, with customized center thickness and edge thickness to ensure compatibility with optical housings or mounts.

c. Optical Materials

Material selection is key to transmission range and thermal stability.

CLZ Precision Optics offers:

BK7 – Excellent for visible applications, with high clarity and stability.

Fused Silica – Ideal for UV and IR wavelengths, low thermal expansion, and superior laser resistance.

CaF₂ and ZnSe – Suitable for infrared and high-power laser applications.

Each material is carefully tested for homogeneity, refractive index consistency, and surface durability.

d. Surface Accuracy and Quality

Surface precision is crucial for minimizing scattering and optical distortion.

Our production achieves:

Surface accuracy: up to λ/10 at 632.8 nm

Scratch-dig quality: 10-5 or 20-10

Surface flatness: up to λ/4 or better

These standards guarantee optical performance even under demanding laboratory and industrial conditions.

e. Coating Options

AR coatings are essential to enhance transmission and reduce reflection loss.

CLZ Precision Optics provides custom anti-reflective coatings optimized for:

UV (200–400 nm)

Visible (400–700 nm)

NIR (700–1550 nm)

IR (3–5 µm / 8–12 µm)

We can design multilayer coatings achieving reflectance below 0.5% per surface.

f. Dimensional and Optical Tolerances

Tight tolerances ensure perfect system alignment.

Typical specifications:

Center thickness: ±0.05 mm

Diameter tolerance: +0.00 / –0.10 mm

Centration: <3 arcmin

Focal length tolerance: ±0.5%

Each lens is inspected using interferometric and spectrophotometric systems before delivery.

Applications of Custom Plano-Concave Lenses

Custom plano-concave lenses manufactured by CLZ Precision Optics are used in:

Laser beam expanders and collimators

Optical testing and interferometry instruments

Imaging and projection systems

Biomedical devices and sensors

Aerospace and defense optical assemblies

Their ability to diverge light precisely makes them indispensable in both scientific research and industrial production environments.

Why Choose Customization Instead of Standard Lenses

Off-the-shelf lenses may not meet the specific spectral, mechanical, or thermal requirements of advanced optical systems.

Through customization, CLZ Precision Optics ensures:

Optimized focal length and ROC

Precision coating for target wavelengths

Compatibility with mechanical mounts

Enhanced performance stability and durability

Our engineering team collaborates closely with customers to analyze system design, simulate optical paths, and recommend the best specifications for long-term performance.

CLZ Precision Optics: Professional Manufacturer You Can Trust

As a professional optical components manufacturer, CLZ Precision Optics has over a decade of expertise in producing custom plano-concave lenses, optical windows, spherical lenses, and thin film coatings.

We provide:

In-house precision polishing and coating facilities

Complete quality control from raw material to finished product

Full inspection reports for curvature, transmission, and surface quality

OEM & ODM services for global optical brands and equipment integrators

Every lens is produced under ISO-compliant quality systems and inspected with advanced interferometers, profilometers, and spectrometers to ensure perfect optical accuracy.

Conclusion

Selecting the right specifications for custom plano-concave lenses determines whether an optical system performs with precision or suffers from inefficiency.

By focusing on radius of curvature, substrate material, surface quality, coating design, and dimensional tolerance, engineers and procurement professionals can achieve consistent and superior results.

With CLZ Precision Optics, you gain more than just a lens — you gain a reliable partner dedicated to custom optical excellence and performance consistency for every application.