Optical coatings for right angle prisms and their benefits

Oct. 11, 2025

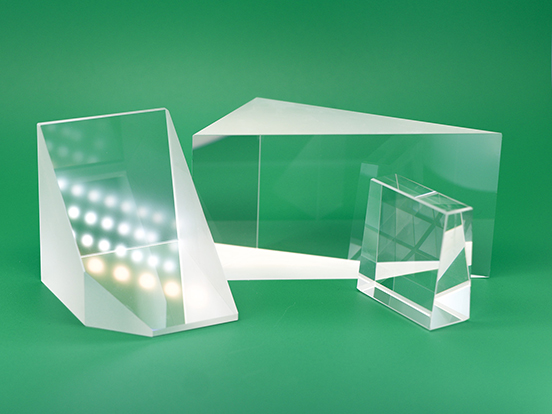

Right angle prisms are indispensable components in optical systems, known for their ability to reflect, invert, and redirect light beams with high precision. However, the performance of these prisms can be significantly enhanced through the use of specialized optical coatings. These coatings not only improve light transmission and reflection efficiency but also enhance durability and adaptability to various working environments. This article explores the types of optical coatings used for right angle prisms, their advantages, and how to choose the right coating for your application — helping buyers make informed decisions for their optical projects.

Understanding Optical Coatings for Right Angle Prisms

Optical coatings are thin-film layers applied to the surfaces of right angle prisms to modify their optical properties. These coatings can increase reflection, reduce unwanted glare, or improve resistance to environmental factors such as humidity and temperature changes. In precision optical assemblies, coatings are often the key to achieving the required optical performance and long-term stability.

Common types of coatings for right angle prisms include:

Dielectric coatings: Used for high reflectivity or anti-reflective purposes. They provide excellent durability and wavelength control.

Metallic coatings (Aluminum, Silver, Gold): Provide broadband reflectivity and are widely used in systems where high reflection across multiple wavelengths is required.

Anti-reflective (AR) coatings: Reduce reflection loss and enhance light transmission through prism surfaces, ensuring higher image brightness and contrast.

Beamsplitter coatings: Allow a controlled portion of light to transmit while reflecting the rest — essential in imaging and measurement systems.

Benefits of Applying Optical Coatings on Right Angle Prisms

Optical coatings offer multiple functional and economic benefits for prism users, especially in demanding optical applications.

a. Improved Light Efficiency

Without coatings, light loss due to reflection or absorption can reach 8% or more per surface. High-quality AR coatings can reduce reflection loss to less than 0.5%, ensuring maximum light throughput.

b. Enhanced Reflection Accuracy

Metallic and dielectric reflective coatings ensure high reflectivity at specific wavelengths or angles, minimizing beam deviation and improving image accuracy in laser systems and measuring instruments.

c. Superior Environmental Resistance

Optical coatings protect the prism surface from humidity, oxidation, and scratches. For example, dielectric coatings can withstand harsh laboratory or industrial conditions, extending the service life of the prism.

d. Optimized Performance for Specific Wavelengths

Custom coatings can be designed for ultraviolet (UV), visible (VIS), or infrared (IR) wavelengths, ensuring compatibility with specialized light sources in applications like spectroscopy, microscopy, or laser optics.

Applications of Coated Right Angle Prisms

Optical coatings make right angle prisms suitable for a wide range of applications:

Laser systems: Coatings ensure efficient light redirection and beam control.

Medical imaging: Anti-reflective coatings provide higher clarity and reduce signal loss.

Aerospace and defense: Durable coatings improve performance under extreme temperature and vibration conditions.

Machine vision and metrology: Beamsplitter coatings help divide and direct light paths precisely.

Telecommunication optics: Coated prisms improve signal transmission efficiency and stability.

Choosing the Right Optical Coating for Your Needs

When selecting coatings for right angle prisms, consider the following factors:

Operating wavelength range — Ensure the coating is optimized for your system’s spectral range.

Required reflectivity or transmission — Choose coatings based on whether your application demands high reflection or high transmission.

Environmental conditions — Opt for durable coatings if the prism will be exposed to humidity, heat, or mechanical stress.

Precision requirements — High-end imaging or measurement systems may need coatings with minimal wavelength shift and high uniformity.

At CLZ Precision Optics, every right angle prism can be customized with precision coatings to meet the exact requirements of your optical system. Our coatings are engineered for superior durability, wavelength accuracy, and surface uniformity, ensuring optimal performance in any environment.

Future Trends in Optical Coatings for Right Angle Prisms

With the rapid evolution of laser and imaging technology, optical coatings are becoming more sophisticated:

Nano-layer coatings for better spectral control.

Hybrid coatings combining AR and mirror functions on different prism faces.

Environmentally stable coatings resistant to thermal cycling and UV degradation.

These innovations will continue to expand the potential applications of right angle prisms in scientific, medical, and industrial fields.

Conclusion

Optical coatings are essential to unlocking the full performance of right angle prisms. From improved transmission and reflection control to enhanced durability, coatings play a vital role in determining the efficiency and reliability of optical systems. Whether you are building a high-precision laser instrument or an imaging device, selecting the right coated prism is a key factor for long-term success.

CLZ Precision Optics provides custom right angle prisms with a variety of advanced optical coatings, ensuring that your system delivers consistent, accurate, and high-quality optical performance.