Plano-Concave Lenses for UV and IR Applications: Materials, Performance, and Design Considerations

Jan. 13, 2026

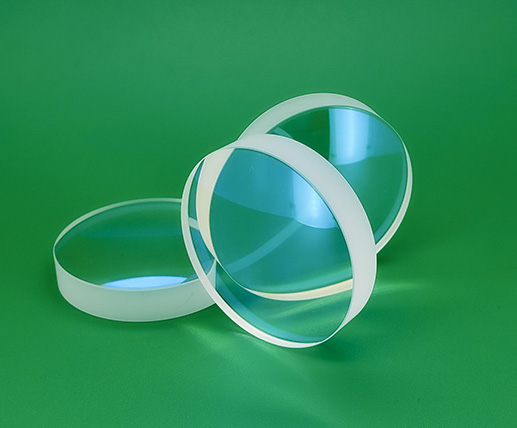

Plano-concave lenses are widely used optical components for beam expansion, divergence control, and aberration correction. In ultraviolet (UV) and infrared (IR) applications, however, lens selection becomes more complex due to wavelength sensitivity, material transmission limits, and coating requirements.

This article provides a comprehensive overview of plano-concave lenses for UV and IR applications, focusing on material options, optical performance, typical use cases, and key factors engineers should consider when specifying lenses for short- and long-wavelength systems.

What Is a Plano-Concave Lens?

A plano-concave lens consists of:

One flat (plano) surface

One inward-curving concave surface

It is a negative focal length lens, primarily used to:

Diverge collimated light

Expand laser beams

Reduce focal length in optical systems

Correct spherical aberration when paired with positive lenses

Plano-concave lenses are commonly used in laser optics, spectroscopy, imaging systems, and scientific instruments, especially where beam shaping and wavelength control are critical.

Why UV and IR Applications Require Specialized Plano-Concave Lenses

Standard optical glass performs well in the visible spectrum but often fails in UV or IR ranges due to:

Poor transmission

High absorption

Thermal instability

Surface degradation

For UV and IR systems, material transparency and coating compatibility become the most important selection criteria.

Plano-Concave Lenses for UV Applications

UV Wavelength Ranges

Near-UV (NUV): 300–400 nm

Deep UV (DUV): 190–300 nm

Vacuum UV (VUV): <190 nm

Each UV range demands different optical materials.

Common Materials for UV Plano-Concave Lenses

Fused Silica (UV Grade)

Excellent transmission from ~180 nm to 2.2 μm

Low fluorescence

High laser damage threshold

Excellent thermal stability

Typical UV applications:

UV laser beam expanders

Photolithography

UV spectroscopy

Semiconductor inspection

Calcium Fluoride (CaF₂)

High transmission down to ~130 nm

Extremely low absorption in deep UV

Low refractive index

Ideal for:

Excimer lasers

DUV imaging systems

High-precision UV optics

Magnesium Fluoride (MgF₂)

Transmission down to ~120 nm

High resistance to UV-induced degradation

Often used in:

Vacuum UV systems

Space and aerospace optics

UV Coating Considerations

For UV optics, coatings must:

Maintain low absorption

Avoid solarization

Withstand high photon energy

Common UV coatings include:

UV MgF₂ anti-reflection coatings

Deep UV broadband AR coatings

In some high-power UV systems, uncoated fused silica lenses are still used to avoid coating damage.

Plano-Concave Lenses for IR Applications

IR Wavelength Ranges

Near-IR (NIR): 0.75–2.5 μm

Mid-IR (MIR): 3–5 μm

Long-Wave IR (LWIR): 8–14 μm

Material choice varies significantly across these ranges.

Common Materials for IR Plano-Concave Lenses

Infrared Fused Silica (NIR)

Good transmission up to ~2.2 μm

High durability and low thermal expansion

Applications:

NIR imaging

Fiber laser systems

Industrial sensing

Silicon (Si)

Transmission from ~1.2 μm to 8 μm

High refractive index

Excellent thermal conductivity

Used in:

Mid-IR optics

Thermal imaging

CO₂ laser pre-alignment

Germanium (Ge)

Transmission from ~2 μm to 14 μm

High refractive index

Sensitive to temperature changes

Common IR uses:

Thermal cameras

LWIR imaging systems

Military and surveillance optics

Zinc Selenide (ZnSe)

Wide transmission range: 0.6–20 μm

Low absorption at 10.6 μm

Ideal for:

CO₂ laser beam expanders

High-power IR laser systems

IR Coating Options

IR plano-concave lenses often use:

BBAR coatings for IR ranges

DLC coatings for durability

Anti-reflection coatings optimized for CO₂ laser wavelengths

Proper coating selection improves transmission and reduces thermal lensing effects.

Plano-Concave Lens Orientation: A Critical Design Detail

For optimal performance:

The curved surface should face the collimated beam

The plano surface should face the focal point

This orientation:

Minimizes spherical aberration

Improves beam quality in UV and IR systems

This principle is widely cited in top-ranking optics manufacturer documentation.

Typical Applications of UV & IR Plano-Concave Lenses

UV Applications

UV laser beam expansion

Fluorescence imaging

UV curing systems

Semiconductor lithography

IR Applications

Thermal imaging systems

IR spectroscopy

CO₂ laser optics

Industrial sensing and monitoring

Key Buying Considerations for UV and IR Plano-Concave Lenses

When sourcing lenses, engineers should evaluate:

Target wavelength range

Transmission efficiency

Laser power and damage threshold

Environmental conditions (temperature, humidity)

Coating durability

Surface quality and scratch-dig specs

For OEM and industrial users, custom plano-concave lenses with optimized materials and coatings often deliver the best system performance.

Conclusion

Plano-concave lenses play a critical role in both UV and IR optical systems, but their performance depends heavily on material choice, coating design, and system integration.

UV applications prioritize high transmission and resistance to photon damage

IR applications demand thermal stability and wavelength-specific materials

By selecting the correct plano-concave lens material and coating, optical engineers can significantly improve system efficiency, reliability, and long-term performance.