Optical Windows for High-Power Laser Systems

Jun. 17, 2025

Introduction

In high-power laser systems, every optical component must be carefully selected to maintain beam quality, minimize power loss, and withstand intense energy exposure. Optical windows play a vital role in protecting sensitive internal components while preserving the integrity of the laser beam. This article explores the essential factors to consider when selecting optical windows for high-power laser applications.

What Are Optical Windows?

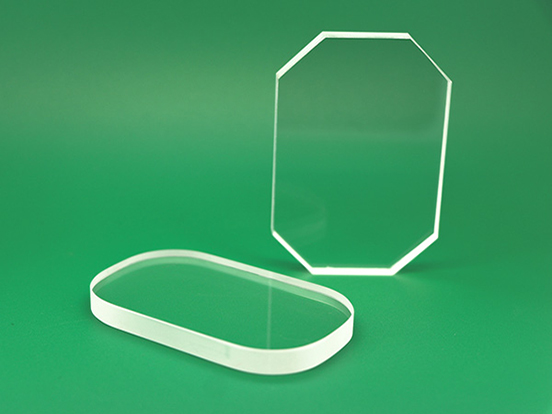

Optical windows are flat, transparent optical components that separate two different environments while allowing light to pass through with minimal distortion or reflection. In high-power laser systems, these windows must offer exceptional transmission, surface flatness, and resistance to laser-induced damage.

Key Requirements for Laser Optical Windows

High Laser Damage Threshold (LDT): The ability to endure high-power laser energy without surface or bulk damage.

High Transmission: Low absorption and scatter across the operating wavelength range.

Excellent Surface Quality: Surface imperfections can cause beam distortion, scattering, and hot spots.

Precision Surface Flatness: Typically λ/10 or better for maintaining beam wavefront accuracy.

Appropriate Coatings: Anti-reflective coatings tailored to the laser’s wavelength improve transmission and reduce reflection losses.

Common Materials for High-Power Laser Windows

The material selection is critical in determining the window's optical and thermal performance:

Fused Silica: Excellent UV to IR transmission, high LDT, low thermal expansion, and resistance to thermal shock.

Sapphire: Extremely hard and durable, high thermal conductivity, suitable for harsh environments and mid-IR applications.

BK7 (Optical Glass): Cost-effective for low to moderate power systems in the visible to near-IR range.

Calcium Fluoride (CaF2): Ideal for UV and high-power IR systems, with low absorption and high LDT.

Anti-Reflective (AR) Coatings for Laser Windows

Uncoated windows reflect approximately 4-8% of incident light per surface, which is unacceptable in high-power laser systems. Applying custom AR coatings significantly enhances transmission and reduces energy loss and potential back reflections that could damage upstream optics.

Types of AR Coatings:

Single-Layer AR Coating: Economical, narrowband performance.

Broadband AR Coating: Effective across a wider wavelength range.

V-Coating: Extremely low reflectance at a specific wavelength, ideal for laser lines.

Laser-Induced Damage Threshold (LIDT)

The Laser-Induced Damage Threshold (LIDT) is the maximum laser energy density (in J/cm²) a window can withstand without damage. Factors influencing LIDT include material type, surface quality, coating, and pulse duration. Fused silica windows, for example, typically offer higher LIDT values than BK7 in both continuous wave (CW) and pulsed laser operations.

Recommended Applications

| Material | Ideal Use |

|---|---|

| Fused Silica | High-energy UV, visible, and IR laser systems |

| Sapphire | Industrial lasers, harsh environments, and high thermal load optics |

| BK7 | Low- to mid-power visible laser systems |

| Calcium Fluoride | Excimer lasers, UV lithography, and IR spectroscopy |

Why Choose CLZ Optical Co., Ltd.?

At CLZ Optical Co., Ltd., we specialize in manufacturing high-precision optical windows tailored for high-power laser systems. Our advanced fabrication and coating processes ensure windows with superior surface flatness, high LDT, and optimal transmission. We offer custom sizes, materials, and AR coatings to match your exact laser specifications.

Conclusion

Optical windows are critical components in high-power laser systems, where beam integrity and durability directly affect system performance and longevity. By carefully selecting appropriate materials, coatings, and specifications, you can significantly improve operational efficiency and reduce maintenance costs. Contact CLZ Optical Co., Ltd. today to discuss your custom optical window requirements for laser applications.