How to improve the CO2 laser damage resistance of Fused Silica Precision Lenses?

Jan. 14, 2020

Fused Silica is an amorphous state of silicon oxide. It is a typical glass. Its atomic structure is long-range disordered. It provides its high use temperature and low thermal expansion coefficient through three-dimensional cross-linking. As a Fused Silica Precision Lenses Supplier, share with you.

Improving the laser damage resistance of Fused Silica Precision Lenses are the main element that guarantees the load capacity of high-power solid-state laser devices. However, laser-induced damage on the surface of optical components is still a big "bottleneck".

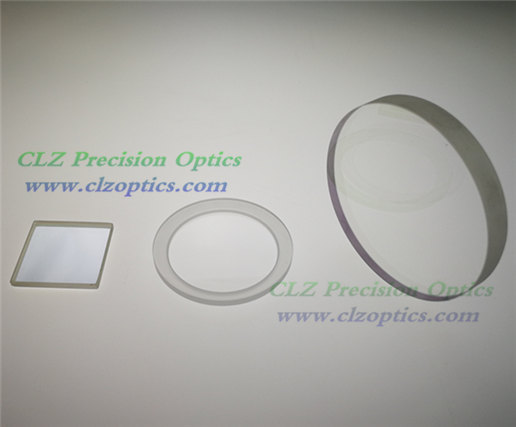

UV Grade Fused Silica Lenses

(1) By studying the characteristics and types of scratches on the surface of fused silica, the final result is obtained: the optical elements can be divided into lateral, radial, Hertz cone and "smearing" scratches from the scratch form; from the formation, properties Can be divided into plastic, brittle and mixed scratches. The shape of the damage point is directly related to the shape of the irradiated laser spot. If the spot is Gaussian, the shape of the damage point can be divided into three types: pitting, "shell" and "violet" damage. If the light spot is a spatially flat-topped light spot, in addition to the damage of the above three shapes, flat-topped damage will also be formed.

(2) Theoretically researched the physical effects of melting, gasification and thermal stress caused by the interaction of CO2 laser and fused silica material, and analyzed the reasons for the melting, gasification and ablation phenomenon when CO2 laser acts on the surface of the quartz. And get the corresponding calculation formula.

(3) In-depth research on the method of repairing chronological scratches on fused silica optical elements, the results show that: for the dense scratches on the surface of optical elements, in order to ensure the repair effect, the CO2 laser power is gradually increased from low to high for multiple scans. Repair is most appropriate.

(4) The method for repairing various dimensional damage points on the surface of fused silica optical elements is studied. The results show that CO2 laser can be used to repair damage points with a lateral size of fewer than 400 μm and a depth of fewer than 200 μm; for a lateral size of 400 μm and 600 μm and a depth of 200 μm and 300 μm The damaged points are repaired by a combination of HF etching and CO2 laser.

(5) During the repair process, there will be an ablation debris and bubble generation mechanism that affects the threshold of the repair point. It can be divided into two types: light ablation and severe ablation. Large spotlight passivation and HF etching can be used to remove it.

(6) The characteristics and elimination methods of residual stress after CO2 laser repairing the damage point. These include two types of annealing: isothermal annealing and isochronous annealing. The effect of annealing temperature on the residual stress is more obvious. For the residual stress obtained by the same repair method on the same component, as long as the annealing parameters can eliminate the residual stress obtained by the maximum spot size CO2 laser.

Our company also has UV Grade Fused Silica Lenses on sale, welcome to consult.