Guide to Understanding the Operating Process of Fused Silica

Nov. 30, 2023

Introduction to Fused Silica

Fused silica, often referred to as fused quartz, is a material of remarkable versatility and utility across various industries. It is a high-purity form of silicon dioxide (SiO2) that is manufactured through a complex process involving melting crystalline silica at extremely high temperatures and then cooling it down rapidly to form an amorphous (non-crystalline) solid. The resulting material exhibits exceptional optical, thermal, and mechanical properties, making it indispensable in a wide range of applications.

Understanding the Manufacturing Process

Melting and Purification

The manufacturing process of fused silica begins with the selection of high-quality raw materials, typically natural quartz crystals or silica sand. These raw materials undergo a meticulous purification process to remove impurities, ensuring the final product's exceptional purity and clarity.

Fusion and Homogenization

Once purified, the silica is fed into a high-temperature furnace, where it undergoes fusion at temperatures exceeding 2000 degrees Celsius. During this process, the silica transforms into a molten state, allowing it to be shaped and molded into desired forms. The molten silica is then carefully homogenized to ensure uniformity in composition and properties throughout the material.

Cooling and Solidification

After the fusion and homogenization stages, the molten silica is rapidly cooled to induce solidification. This rapid cooling process is crucial for preventing the formation of crystalline structures, which could compromise the material's optical transparency and mechanical strength. The resulting solidified silica, known as fused silica, retains its amorphous structure and exhibits exceptional purity and homogeneity.

Applications of Fused Silica

Fused silica's unique combination of properties makes it highly sought after in various industrial and scientific applications:

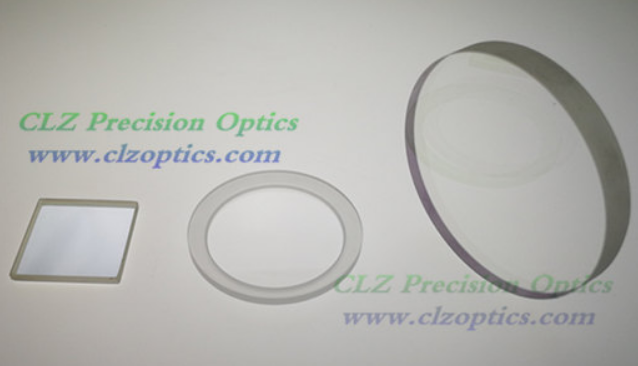

Optics and Photonics

In the field of optics and photonics, fused silica is prized for its exceptional optical clarity, low coefficient of thermal expansion, and resistance to high temperatures. It is widely used in the manufacturing of lenses, mirrors, prisms, and optical fibers for applications ranging from laser systems to telecommunications.

Semiconductor Manufacturing

Fused silica plays a critical role in semiconductor manufacturing processes, where its high purity and thermal stability are essential for fabricating integrated circuits with nanoscale precision. It is used as a substrate material for photomasks, as well as in the production of crucibles and quartzware for semiconductor wafer processing.

Aerospace and Defense

In aerospace and defense applications, fused silica is valued for its lightweight, high-strength properties, as well as its ability to withstand extreme temperatures and harsh environmental conditions. It finds use in components such as windows, domes, and thermal insulation for spacecraft, missiles, and military optics.

High-Temperature Furnace Components

Due to its exceptional thermal stability and resistance to thermal shock, fused silica is commonly employed in the construction of high-temperature furnace components such as crucibles, thermocouple protection tubes, and refractory linings. These components play a crucial role in various industrial processes, including glass melting, metal casting, and semiconductor crystal growth.

Conclusion

In conclusion, the operating process of fused silica involves a series of intricate steps, from raw material selection and purification to melting, homogenization, and solidification. The resulting material possesses unparalleled optical clarity, thermal stability, and mechanical strength, making it indispensable across a wide range of industries and applications. Whether in optics, semiconductor manufacturing, aerospace, or high-temperature furnaces, fused silica continues to demonstrate its versatility and value in enabling technological advancements and innovation.