How to increase the service life of Optical Glass Lenses?

Nov. 19, 2019

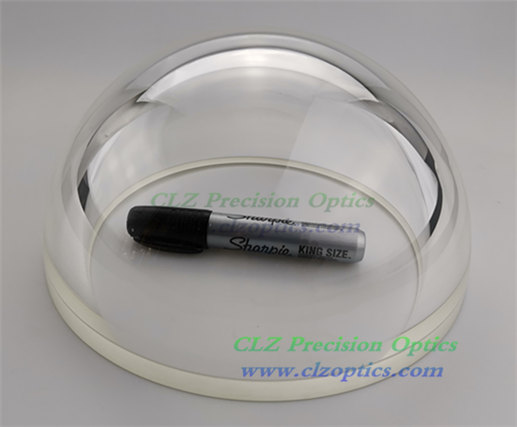

In today's era, everyone has become a low-headed family, so this also brings opportunities for the use of optical glass. Optical Glass Lenses China has generally entered our lives, but several people know what to do. Protect her and clean it? Make it last longer and more durable? Today, Optical Domes Supplier and everyone shares how to increase the life of optical glass?

Keeping the optical glass sheets clean often increases the life of the optical glass sheets. Because pollution causes many problems in the lens, the uneven distribution of the laser power during reflection makes the lens base temperature high and the marginal temperature low, and this change is optically called the lens effect.

Optical Glass Lenses China

Failure to comply with the requirements and attention to lens finishing, random handling will create new pollution or even scratch the optical glass, resulting in unnecessary losses. Usually, be careful not to let the mirror-touch the hard object directly. When scrubbing, it is best to clean it with water (or a small amount of detergent), then use a special test cloth or excellent cotton paper to blot the water droplets on the lens. If the lens is not scratched, it can't be used all the time.

The processing of the lens is formed by high temperature or ultraviolet curing of the liquefied monomer. As the operating cycle becomes longer and the environment and temperature change, the surface of the lens and the material of the lens itself change, resulting in light scattering, reduced comfort, and application time. Long will have dry eyes and bloated performance. At this time, it is necessary to replace the optical glass.

Optical glass and daily-use glass have a large amount of grinding processing, so the grinding efficiency of corundum or natural corundum is generally high. The flat glass has a small amount of grinding processing, but the area is large and the amount is large, and the cheap quartz sand is generally used. Commonly used polishing materials include red powder (iron oxide), cerium oxide, chromium oxide, zirconium oxide, cerium oxide, etc., and feldspar powder is also used for daily glass processing. New polishing technology for optical products for optical glass processing, traditional grinding and polishing methods are not suitable for accuracy and efficiency. Many new processing technologies have been developed, such as CNC grinding and polishing technology, ion beam polishing technology, stress plate polishing technology, ultra-smooth surface processing technology, ductile grinding processing, elastic emission polishing, laser polishing, vibration polishing, etc. These new technologies have fully adapted to the rapid development of the optical field. The new processing technology of the optical lens is both edge detection and side correction. It not only has high processing precision, but also the processing speed is increased several times to several tens of times. The dependence on artificial technology is very small, and the new grinding and polishing technology is intelligent. Very high and high repeatability. CNC grinding and polishing, stress plate polishing technology, etc., specializing in the processing of spherical and aspheric optical lenses, very specialized. Our company also has Concave Mirror on sale, welcome to come and consult.