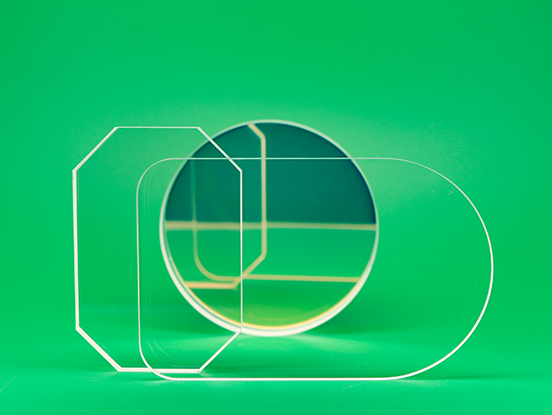

Optical Windows: Properties Types and Specifications

Sep. 21, 2023

Optical windows are fundamental components in various optical systems, serving as protective barriers that allow light to pass through while maintaining the integrity of the system. These windows are crucial for controlling environmental conditions, preventing contamination, and enabling precise optical measurements. In this article, we will delve into the properties, types, and specifications of optical windows, shedding light on their importance in optical engineering.

Understanding Optical Windows

An optical window is a flat, transparent component made from optical-grade materials such as glass, quartz, or other materials with desirable optical properties. These windows are designed to allow optical components to interact with external environments while safeguarding the delicate internal elements of optical systems from dust, moisture, and contaminants. Optical windows are employed in a wide range of applications, from scientific research and aerospace to industrial imaging and telecommunications.

Properties of Optical Windows

1. Optical Transparency:

The primary property of an optical window is its ability to transmit light with minimal distortion or absorption. This property ensures that the optical quality of the system is not compromised as light passes through the window.

2. Refractive Index:

The refractive index of the window material affects the way light is bent as it enters and exits the window. Matching the refractive indices of adjacent materials minimizes reflection and refraction, leading to improved optical performance.

3. Mechanical Durability:

Optical windows must be mechanically robust to withstand external forces, temperature fluctuations, and other environmental factors. The mechanical durability ensures the long-term reliability of optical systems.

4. Surface Quality:

A smooth and high-quality surface finish is essential for minimizing scattering and maintaining image clarity. The surface quality of optical windows is often specified in terms of scratch-dig specifications.

5. Coating Compatibility:

Many optical windows are coated with anti-reflective, reflective, or protective coatings. The material's compatibility with coatings is vital to achieve desired optical properties and performance.

6. Thermal Expansion:

The coefficient of thermal expansion (CTE) of the window material must be considered to prevent warping or stress-induced deformation due to temperature variations.

Types of Optical Windows

1. Flat Windows:

Flat optical windows are the most common type, featuring parallel surfaces. They are used in applications where minimal optical distortion is required, such as protective covers for optical sensors and detectors.

2. Plano-Convex and Plano-Concave Windows:

Plano-convex and plano-concave optical windows have one flat surface and one curved surface. They are used to focus or diverge light, respectively, and find applications in imaging systems and beam manipulation.

3. Wedge Windows:

Wedge windows have one tapered edge, causing light to be deflected. These windows are used to minimize reflections in optical systems and are often employed in laser applications.

4. Brewster Windows:

Brewster windows are designed to minimize reflections for light incident at a specific angle (Brewster's angle). They are commonly used in laser cavities and polarization-sensitive setups.

Specifications and Considerations

When selecting optical windows, several specifications and considerations should be taken into account:

- Material: Choose a material that meets the optical, mechanical, and environmental requirements of the application. Common materials include optical glasses, fused silica, and crystals.

- Thickness: The thickness of the window affects its mechanical strength and thermal stability. Thicker windows provide greater durability but may also introduce more optical distortion.

- Diameter: The diameter of the window determines the field of view and the amount of light transmitted. Choose a diameter that suits the optical system's requirements.

- Coatings: Consider whether coatings are needed to enhance transmission, reduce reflections, or provide protective layers. Coatings can significantly impact the performance of optical windows.

- Environmental Conditions: Depending on the operating environment, consider factors such as temperature, humidity, and exposure to chemicals when selecting a suitable window material.

- Tolerance and Surface Quality: Specify the required tolerances for dimensions and surface quality to ensure that the window meets the desired optical performance.

Applications of Optical Windows

1. Imaging Systems:

Optical windows are integral components of imaging systems, allowing light to enter and exit cameras, telescopes, and microscopes while maintaining image quality.

2. Laser Systems:

Laser systems utilize optical windows to control and manipulate laser beams, minimizing reflections and maintaining laser cavity integrity.

3. Spectroscopy:

In spectroscopic setups, optical windows allow precise control of light paths and facilitate accurate measurements of spectral properties.

4. Aerospace and Defense:

Aerospace and defense applications use optical windows to protect sensors and cameras from harsh environments, such as high speeds, temperature extremes, and atmospheric conditions.

5. Industrial Sensing:

In industrial sensing applications, optical windows protect sensors and detectors from contaminants and mechanical stress while allowing accurate measurements.

Conclusion

Optical windows are essential components that provide a gateway for light to enter and exit optical systems while safeguarding delicate internal elements. With their diverse types, properties, and applications, optical windows play a crucial role in various industries, enabling precise optical measurements, imaging, and light manipulation. By carefully considering material properties, specifications, and environmental conditions, optical engineers can select the right optical windows to optimize the performance and reliability of their optical systems.

For a comprehensive range of high-quality optical windows and custom optical components, visit [https://www.clzoptics.com/products/]