Fused silica in optical components

Nov. 10, 2021

Optics are critical for a range of applications, from analytical equipment to communications devices, medical diagnostic equipment, aerospace instruments, and defense equipment. They are used for diffraction, reflection, refraction, and diffraction of various wavelengths of light to enhance, amplify and direct light through transparent lenses and optical components.

Due to the highly precise nature of optical applications, optical components must be manufactured with a high degree of clarity and precision. Fused silica is particularly well suited for optical applications. It is valued for its excellent clarity, durability, and thermal properties for use in extreme environments where other materials are not suitable.

What is fused silica?

Fused silica is amorphous silica. It can be obtained, for example, by melting silica powder so that the particles are fused together and cooled fast enough to avoid crystallization. Fused silica in a more or less purified form belongs to the most important optical glasses or, more generally, optical materials for various bulk optical components and optical fibers.

There are also various silicate glasses that have fused silica as their main component but contain other substances such as soda, alumina, germanium oxide, or lime. They typically have a much lower glass transition temperature and differ from pure silica in many other ways, such as in the range of transparency and coefficient of thermal expansion.

Fused silica is sometimes referred to as quartz glass. However, it should be remembered that it is an amorphous material, while quartz is crystalline.

Why use fused silica in optical components?

In optics, fused silica provides excellent UV transmission and can be manufactured to facilitate the transmission of infrared wavelengths. Coupled with low refractive index variation, it exhibits ideal optical qualities for high-precision optical applications. In addition, the physical properties of fused silica glass make it particularly suitable for high-performance applications in harsh conditions. Some of its most useful properties include:

▷ Extremely high hardness

▷ High-temperature resistance

▷ Broad optical transmission in the UV spectrum, but some IR fused silica glass can be used

▷ Extremely low permeability

▷ Low coefficient of thermal expansion (CTE)

▷ High chemical purity

▷ Excellent corrosion resistance

▷ Excellent electrical insulation properties

▷ The low refractive index change

▷ Low birefringence value

▷ Large size capability

▷ State-of-the-art homogenization level

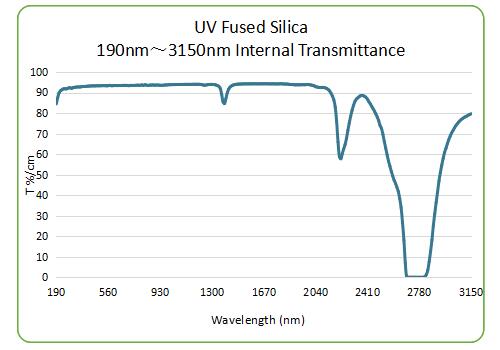

Internal Transmittance of high-quality JGS1 from China:

Thermal properties

Fused silica has exceptional thermal properties that make it ideal for use in optical components. With its low coefficient of thermal expansion (CTE) and extremely high-temperature resistance, the accuracy of optical components made of fused silica can be trusted even in high-temperature applications. The extremely low thermal conductivity of fused silica makes it an excellent insulating material. Fused silica is extremely resistant to thermal shock and can withstand extreme temperature fluctuations during the manufacturing process, making it easier to quench quartz glass components quickly without compromising the strength of the material.

What optical applications use fused silica?

The high strength and unique thermal properties of fused silica make it ideal for a variety of optical applications that require a high level of durability, precision, and tolerance to wide temperature fluctuations.

Some of the most common optical applications that benefit from fused silica components include

▷ Microwave and millimeter-wave components

▷ High-temperature lamp housings

▷ Temperature insensitive optics support

▷ Aerospace radar windows

▷ Lenses and mirrors in highly variable temperature states

We produce fused silica windows every day. Suitable for less harsh environments where good UV performance is required. Custom sizes are manufactured to your exact specifications, creating a cost effective window for your optical application. Fused silica is available in a variety of qualities and grades and transmits well at a variety of wavelengths.