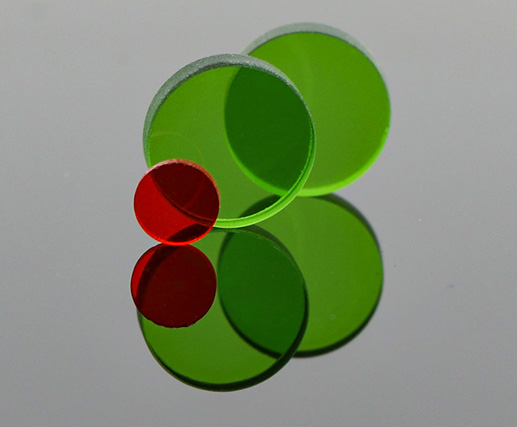

Custom Optical Glass Color Filters: What to Know

Dec. 22, 2025

Custom optical glass color filters are essential components in optical systems that require precise wavelength control, high durability, and consistent long-term performance. For applications where standard filters cannot meet exact spectral or mechanical requirements, customized optical glass solutions provide a reliable and efficient alternative.

This article explains what buyers, engineers, and system integrators should know before sourcing custom optical glass color filters, focusing on performance, design considerations, and real-world applications.

What Are Custom Optical Glass Color Filters?

Custom optical glass color filters are specially engineered optical elements designed to selectively transmit, absorb, or block specific wavelength ranges. Unlike standard catalog filters, custom filters are manufactured according to application-specific parameters such as wavelength response, physical dimensions, glass composition, and environmental resistance.

They are widely used in systems where accuracy, stability, and repeatability are critical, including industrial imaging, medical diagnostics, scientific instruments, and optical sensing equipment.

Why Custom Optical Glass Color Filters Are Preferred in Professional Applications

One of the main reasons buyers choose custom optical glass color filters is the ability to achieve precise spectral performance. Customization allows engineers to define exact cut-on and cut-off wavelengths, ensuring that only the desired light reaches the sensor or imaging system.

Another advantage is long-term stability. Optical glass filters maintain consistent performance under heat, humidity, and prolonged light exposure, making them more reliable than polymer-based alternatives. This stability reduces recalibration needs and extends system lifespan.

Custom filters also support better system integration, as thickness, diameter, and mounting tolerances can be optimized to fit existing optical assemblies without redesigning the entire system.

Key Design Factors to Consider When Customizing Optical Glass Color Filters

Spectral Requirements and Wavelength Control

The most critical design factor is defining the required wavelength range. This includes determining the transmission band, blocking range, and acceptable tolerances. Proper spectral design improves image contrast, measurement accuracy, and signal reliability.

Applications such as machine vision or spectroscopy often require narrow and well-defined transmission curves to eliminate background interference.

Optical Glass Material Selection

Different optical glass compositions provide different absorption characteristics and durability levels. Selecting the right glass material affects color stability, resistance to UV or infrared exposure, and overall performance consistency.

For demanding environments, optical glass materials are preferred due to their resistance to aging and environmental degradation.

Thickness and Dimensional Precision

Filter thickness influences absorption depth and spectral behavior. Custom optical glass color filters can be manufactured with tight dimensional tolerances to ensure consistent performance across production batches.

Precise dimensions are especially important for compact optical systems, where space constraints and alignment accuracy are critical.

Surface Quality and Optical Performance

High surface quality minimizes scattering and distortion, which is essential for high-resolution imaging and measurement systems. Custom filters can be produced with controlled surface flatness to support accurate light transmission and reduce optical noise.

This is particularly important in camera systems, microscopes, and precision sensors.

Coatings and Surface Treatments

While many optical glass color filters rely on bulk absorption, surface treatments can further enhance performance. Anti-reflective coatings improve transmission efficiency and reduce unwanted reflections, especially in multi-element optical systems.

Protective coatings can also be applied to improve resistance to moisture, chemicals, and mechanical wear, making filters suitable for harsh industrial or outdoor environments.

Common Applications of Custom Optical Glass Color Filters

In machine vision and industrial inspection systems, custom filters are used to enhance contrast and suppress ambient light, improving defect detection accuracy.

In medical and biomedical imaging, precise wavelength control ensures reliable diagnostics and consistent imaging results across repeated use.

Scientific and laboratory instruments rely on custom optical glass color filters for accurate spectral analysis, ensuring repeatable and verifiable measurements.

Camera and imaging systems use custom filters to improve color fidelity, manage glare, and control spectral balance under different lighting conditions.

Optical sensors and detectors benefit from customized filters that protect sensitive components and allow only relevant wavelengths to reach the detection surface.

Custom Optical Glass Color Filters vs Standard Solutions

Standard filters are suitable for general-purpose applications but often require compromises in performance or integration. Custom optical glass color filters eliminate these compromises by aligning optical, mechanical, and environmental specifications with the system’s actual needs.

Although custom solutions may have a higher initial cost, they typically deliver better reliability, reduced maintenance, and improved overall system efficiency.

Quality Control and Performance Validation

Reputable manufacturers test custom optical glass color filters for spectral accuracy, dimensional precision, and environmental durability. These tests ensure that each filter meets design requirements and performs consistently in real-world conditions.

Quality control is especially important for applications where optical performance directly affects system output or safety.

Procurement Tips for Buyers and Engineers

When sourcing custom optical glass color filters, buyers should clearly communicate performance requirements, operating conditions, and quantity expectations. Providing detailed specifications early in the process helps manufacturers optimize the design and avoid costly revisions.

It is also important to consider scalability, lead time, and technical support when selecting a supplier.

Industry Trends and Future Outlook

The demand for custom optical glass color filters continues to grow with advancements in automation, imaging technology, and precision sensing. Industries increasingly require filters with higher accuracy, better environmental resistance, and compatibility with compact optical designs.

As optical systems become more specialized, customization will remain a key driver of performance and innovation.

Conclusion

Custom optical glass color filters offer unmatched precision, stability, and flexibility for professional optical applications. By understanding design parameters, application needs, and quality considerations, buyers can make informed decisions that enhance system performance and long-term reliability.

For projects where optical accuracy matters, custom optical glass color filters are not just an option—they are a necessity.