Applications of Right Angle Prisms in Laser and Imaging Systems

Jan. 13, 2026

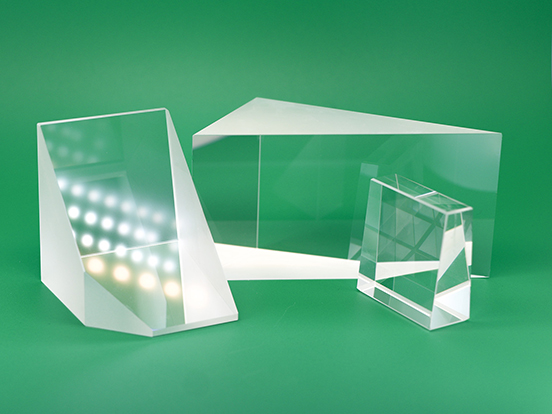

Right angle prisms are among the most widely used optical components in laser systems and imaging instruments. Thanks to their compact geometry, high optical efficiency, and ability to precisely redirect light, they play a critical role in modern optical system design.

From industrial lasers to scientific imaging and machine vision, right angle prisms are essential for beam steering, optical path folding, and image manipulation. This article explores the key applications of right angle prisms in laser and imaging systems, explaining why they are often preferred over mirrors or other prism types.

Why Right Angle Prisms Are Ideal for Laser and Imaging Systems

A right angle prism is a triangular prism with a 90° angle that can redirect light by 90° or 180° using total internal reflection (TIR) or reflective coatings.

Key advantages include:

High reflectivity without metallic coatings (via TIR)

Excellent beam pointing stability

Compact and rigid optical alignment

Broad wavelength compatibility (UV, visible, IR)

Long-term durability in industrial environments

These properties make right angle prisms particularly well suited for precision laser optics and imaging assemblies.

Applications in Laser Systems

1. Laser Beam Steering and Direction Control

One of the most common uses of right angle prisms in laser systems is beam steering.

Redirects laser beams by exactly 90°

Maintains beam quality and polarization

More stable than mirror mounts in vibration-prone environments

Typical laser applications include:

Industrial cutting and marking lasers

Medical laser delivery systems

Scientific research lasers

Compared to mirrors, right angle prisms offer fixed angular accuracy and improved mechanical robustness.

2. Optical Path Folding in Compact Laser Designs

In compact laser modules, available space is often limited. Right angle prisms allow designers to fold optical paths efficiently without increasing system size.

Used in:

OEM laser modules

Fiber-coupled laser systems

Portable laser instruments

By folding the beam path, system designers can:

Reduce enclosure size

Improve optical layout efficiency

Maintain alignment stability

3. Retroreflection and Beam Reversal

When a laser beam enters the hypotenuse face, a right angle prism can reflect the beam back parallel to its original path (180° deviation).

This is widely used in:

Laser interferometers

Alignment and calibration systems

Optical delay lines

Retroreflection using a right angle prism is more stable than mirror-based solutions.

4. High-Power Laser Applications

Right angle prisms are suitable for high-power laser systems when made from appropriate materials such as:

UV fused silica

Optical-grade BK7

IR materials like CaF₂ or ZnSe

Because TIR does not rely on reflective coatings, right angle prisms:

Offer higher laser damage thresholds

Reduce coating failure risks

This makes them ideal for high-energy pulsed and continuous-wave lasers.

Applications in Imaging Systems

1. Image Inversion and Reversion

Right angle prisms naturally invert or reverse images depending on orientation, making them useful in imaging optics for:

Correcting image orientation

Optical system layout optimization

Common imaging uses include:

Microscopy systems

Projection optics

Optical inspection equipment

2. Optical Path Folding in Imaging Devices

Just like in laser systems, right angle prisms help fold optical paths in imaging assemblies to reduce system size.

Used in:

Machine vision cameras

Medical imaging devices

Industrial inspection systems

Compact folded designs are especially valuable in:

Embedded vision systems

Portable imaging equipment

3. Beam Splitting and Combination (with Coatings)

When combined with partial reflective coatings, right angle prisms can function as:

Beam combiners

Beam splitters

This is common in:

Interferometric imaging

Optical measurement systems

Alignment and metrology tools

4. Precision Alignment in Imaging Systems

Right angle prisms provide:

Fixed angular relationships

Repeatable beam deviation

This improves:

System alignment accuracy

Long-term optical stability

As a result, they are widely used in high-precision imaging and measurement instruments.

Material and Coating Choices for Laser & Imaging Use

To perform reliably, right angle prisms must be matched to system requirements:

Common Materials

BK7: visible imaging and general lasers

UV fused silica: UV lasers and high-power applications

CaF₂ / MgF₂: UV and deep-UV imaging

ZnSe / Ge: IR and CO₂ laser systems

Coating Options

AR coatings on entrance/exit faces

Uncoated hypotenuse for TIR

Metallic or dielectric coatings for non-TIR designs

Proper material and coating selection ensures maximum transmission, minimal loss, and long-term durability.

Right Angle Prisms vs Mirrors in Laser and Imaging Systems

Compared to mirrors, right angle prisms offer:

Higher mechanical stability

No need for mirror alignment mounts

Better resistance to environmental changes

Improved repeatability in OEM assemblies

This is why many laser and imaging manufacturers prefer right angle prisms in fixed optical architectures.

Typical Industries Using Right Angle Prisms

Industrial laser processing

Medical and biomedical imaging

Machine vision and automation

Scientific research and spectroscopy

Metrology and optical inspection

Their versatility makes them a standard component across multiple optical industries.

Conclusion

Right angle prisms are indispensable components in laser and imaging systems, offering reliable beam steering, compact optical path folding, and excellent long-term stability. Whether used in high-power laser applications or precision imaging instruments, they deliver a strong balance of performance, durability, and cost efficiency.

For optical engineers and OEM manufacturers, right angle prisms remain one of the most practical and widely adopted solutions in modern optical system design.