How MgF₂ Coating Extends Lens Service Life

May. 27, 2025

Optical components operating in complex environments over extended periods often face challenges such as mechanical wear, chemical corrosion, and contamination, leading to performance degradation and reduced lifespan. Magnesium fluoride (MgF₂) coating, leveraging its unique physicochemical properties, has become a critical technology for enhancing lens durability. This approach not only improves the adaptability of optical components to harsh environments but also offers cost-effectiveness and process feasibility, delivering efficient solutions for industrial, medical, and consumer electronics applications.

How MgF₂ Coating Extends Lens Service Life:

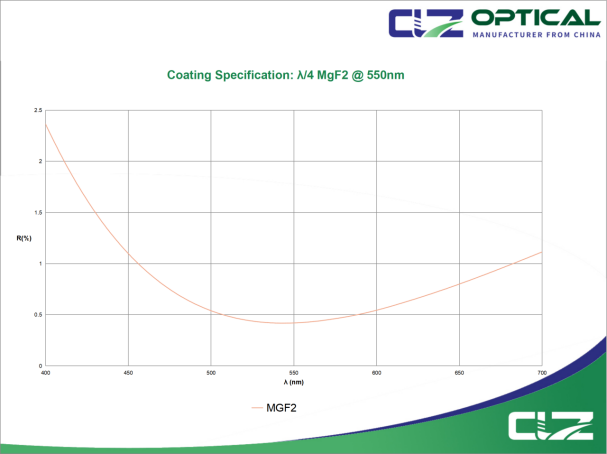

Reduces Surface Reflection & Enhances Light Transmission

MgF₂ minimizes light reflection off the lens surface, increasing light throughput.

Less reflection means reduced stray light and hot spots that could cause localized heating or degradation in high-intensity applications like lasers and projectors.

Less reflected light also reduces the risk of surface photochemical damage.

Protects Against Environmental Factors

Acts as a barrier layer against:

Moisture: Preventing water vapor from interacting with and degrading sensitive optical glass.

Oxidation: Shielding lens surfaces, especially for fluoride-based or soft optical materials.

Chemical corrosion: Reducing the impact of airborne pollutants or mild acids/alkalis in industrial and outdoor environments.

Enhances Surface Hardness & Scratch Resistance

Though MgF₂ itself is not super hard, when properly deposited, it slightly increases the surface durability against minor abrasions compared to bare glass.

This helps maintain optical performance over time in handling and cleaning.

Stabilizes Optical Performance

Without coating, lenses may show performance drift due to surface degradation.

MgF₂ coating maintains consistent anti-reflection properties and image quality over years of use.

Especially valuable in high-precision optics like telescopes, laser systems, and imaging sensors.

Evolution of Coating Technology

Early Challenges and Serendipitous Discoveries

In the late 19th century, rapid advancements in optical instruments highlighted the issue of light reflection on untreated glass surfaces. Scientists observed that glass surfaces reflected approximately 4% of incident light, causing image blurring and energy loss. Natural phenomena—such as acid-etched glass reducing reflection and oil-film interference effects—inspired early attempts at artificial coatings.

Key Breakthroughs and Material Selection

In 1935, German physicist Alexander Smakula at Carl Zeiss AG achieved a decisive breakthrough. Through systematic research on single-layer anti-reflective coatings, he identified magnesium fluoride (MgF₂) as an ideal material due to its low refractive index (~1.38) and chemical stability. Using vacuum evaporation deposition technology, Smakula achieved uniform MgF₂ coatings for the first time, significantly improving optical transmittance and laying the foundation for modern coating techniques.

Industrialization and Technological Advancements

During World War II, demand for military optical equipment accelerated the mass production of MgF₂ coatings. Subsequent advancements, such as the introduction of multilayer coating systems (e.g., combining SiO₂ and TiO₂), expanded their spectral adaptability. Today, MgF₂ coatings serve as a core solution in precision optical systems, supporting advancements in industrial, medical imaging, and consumer electronics fields.

Coating Properties and Protective Mechanisms

Physical Characteristics

The advantages of MgF₂ coatings stem from their low refractive index and high hardness. The low refractive index minimizes surface reflection, enhances light transmission efficiency, and acts as an adaptation layer in multilayer systems, synergizing with high-refractive-index materials to optimize broadband performance (particularly in UV and near-infrared spectra). The tightly packed molecular structure forms a robust physical barrier, resisting scratches, particle impacts, and surface damage.

Chemical Characteristics

MgF₂’s chemical inertness effectively blocks acidic gases and organic contaminants, inhibiting substrate oxidation. The coating remains stable under extreme conditions such as high temperatures and exposure to strong acids or alkalis, ensuring long-term protection for high-reliability optical systems. Notably, while MgF₂ may face limitations in humid environments, integrating it into multilayer structures (e.g., with SiO₂) significantly enhances its comprehensive protective capabilities in complex conditions.

Validation of Practical Applications

Industrial Applications

Microscope lenses coated with MgF₂ exhibit enhanced resistance to organic solvent erosion, reducing cleaning and maintenance frequency. In laser equipment, improved UV-band transmittance ensures stable high-power laser focusing and minimizes energy loss.

Medical Applications

Endoscope lenses retain stable optical performance even after repeated high-temperature and high-pressure sterilization, preventing image degradation caused by disinfectant corrosion. In ophthalmic laser instruments, MgF₂ coatings optimize energy distribution, reducing thermal damage risks to healthy tissues during procedures.

Preparation Processes and Technologies

Vacuum deposition technology is the cornerstone of MgF₂ coating fabrication, characterized by mature processes and controllable parameters. By precisely regulating evaporation rates and substrate temperatures, uniform nanometer-scale thickness coverage is achieved, eliminating interference fringes that disrupt imaging. In mass production, per-unit costs are reduced compared to traditional methods, making it ideal for high-volume manufacturing (e.g., consumer electronics lenses). Online monitoring systems enable real-time analysis of transmittance and coating adhesion, ensuring batch consistency and improving yield rates.

Conclusion

The magnesium fluoride (MgF₂) coating extends the service life of lenses in harsh environments through a dual protective mechanism: forming a physical barrier and leveraging chemical inertness. Its low refractive index and compatibility with multilayer coating systems further broaden its applications in precision optical systems. Combined with high-efficiency mass production techniques, this technology has become a core solution in industrial equipment, medical instruments, and high-end consumer electronics, providing reliable assurance for the long-term stable operation of optical components.