Why sapphire is the material of first choice for optical windows

May. 16, 2025

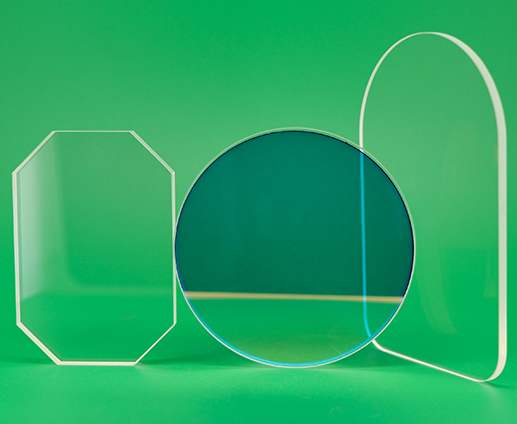

In optical systems, Optical Windows are key elements for protecting sensors, lasers or other precision optical components, while needing to ensure excellent optical performance. Among the many materials available, sapphire (Sapphire, Al₂O₃) is the material of choice for high-end optical windows due to its unique physical and chemical properties.

1. The core characteristics of sapphire

(1) Ultra-high hardness - Mohs hardness of 9, second only to diamond

The Mohs hardness of sapphire is as high as 9, second only to diamond (10), much higher than ordinary glass (5-6) and quartz (7). This makes the sapphire window extremely scratch and wear resistant, suitable for long-term exposure to sand, dust, friction and other harsh environments in applications such as:

-Military equipment (missile fairings, viewing windows for armored vehicles)

-Industrial sensors (protective windows for lasers in highly abrasive environments)

-Consumer electronics (smartphone camera covers, smartwatch screens)

(2) High transmittance over a wide wavelength range - ultraviolet (UV) to infrared (IR)

Sapphire has excellent transmittance over the 0.15~5.5μm wavelength range, covering:

-Ultraviolet (UV): for deep-ultraviolet (UV) lasers and photolithography equipment

-Visible: for high-precision optical instruments

-Mid-infrared: for thermal imaging and infrared detection

In contrast, ordinary optical glass (e.g., BK7) has low transmittance in the UV and IR bands, while ZnSe, although having good IR transmittance, performs poorly in the UV and visible bands.

(3) High temperature resistance - melting point up to 2050°C

Sapphire has a melting point of up to 2050°C and a thermal conductivity (35 W/m-K) that is superior to quartz (1.4 W/m-K) and glass (~1 W/m-K), making it suitable for:

High temperature observation windows (aero-engine combustion chambers, plasma equipment)

High power laser systems (reducing thermal lensing effects)

(4) Excellent chemical resistance

Sapphire is virtually insoluble in strong acids (except for HF, for example), strong bases and organic solvents, far superior to ZnSe (easily corroded by acids) and ordinary glass (susceptible to hydrofluoric acid). This makes it excellent in the following fields:

Semiconductor manufacturing (corrosion-resistant wafer handling equipment windows)

Deep-sea exploration (resistance to high pressure and salt water corrosion)

2. Sapphire limitations and applicable scenarios

Despite its excellent performance, sapphire still has some limitations:

High cost: Crystal growth and precision processing are difficult, and the price is higher than glass and quartz.

Processing difficulty: Ultra-high hardness makes cutting and polishing complex, and it is easy to cause edge cracking.

Not suitable for long-wave infrared (>5.5 μm): If far-infrared light transmission is required, ZnSe or Ge must be selected.

3. Application

Military/Aerospace: missile guide head, high energy laser weapon window;

Industrial laser: high-power CO₂ laser protective lenses;

Semiconductor / medical: plasma etching equipment observation window, endoscope;

Consumer electronics: smart phone lens cover, fingerprint identification module;

Sapphire has become the material of choice for high-end optical window sheets due to its comprehensive advantages of ultra-high hardness, broadband light transmission, high temperature resistance, and corrosion resistance. Despite its high cost, its performance far exceeds that of quartz, glass and ZnSe in harsh environments such as military, laser technology, semiconductors, etc. In the future, with the advancement of processing technology, the application range of sapphire window sheet will be further expanded and continue to lead the development trend of optical materials.