The Advantages of AR coating Optical Windows

May. 21, 2025

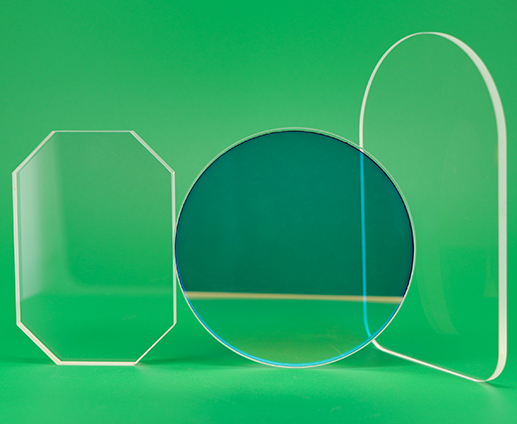

In modern optical systems, the optical windows, as a key element in the optical path, has a direct impact on the imaging quality and energy transfer efficiency of the entire system. Due to the difference between the refractive index of the material itself and that of the air, the traditional optical windows produces significant reflection losses at the interface, leading to a decrease in light transmittance and an increase in stray light. To solve this problem, the technology of transmittance enhancement film has emerged and has gradually become the core means to improve the performance of optical windows.

How Transmission Enhancement Coating Works

The core principle of permeation enhancement membrane technology is based on the interference effect of light. When light propagates from one medium to another medium with a different refractive index, reflection and refraction will occur at the interface. The introduction of one or more layers of specific optical thickness of the film at the interface can make the interface between the reflected light produce phase cancellation interference, thereby reducing the overall reflectivity.

Single-layer permeation-enhancing membranes are the simplest construction, and their optical thickness (physical thickness multiplied by refractive index) is usually designed to be one-quarter of the operating wavelength. According to Fresnel's equation, optimal reflection reduction is achieved when the refractive index of the film layer is equal to the square root of the product of the refractive index of the substrate and the refractive index of air. For example, for a glass substrate with a refractive index of 1.52, the ideal single-layer film should have a refractive index of 1.23. Commonly used single-layer film materials include magnesium fluoride (MgF2, with a refractive index of about 1.38), which does not exactly match the theoretical value, but has been shown to significantly reduce reflectivity.

Multi-layer transmittance enhancement films can achieve lower reflectance over a wider spectral range by combining layers with different refractive indices and thicknesses. Typical designs include membrane systems with alternating stacks of high and low refractive index materials, such as TiO2/SiO2, Ta2O5/SiO2, and other combinations. Through computer-optimized designs, modern multilayer permeation enhancement membranes can achieve excellent performance in the visible wavelength band (400-700 nm) with an average reflectance of less than 0.5%.

Broadband permeation enhancement membrane technology further extends the operating wavelength range, with some designs covering a wide spectral region from the ultraviolet to the near infrared. Such film systems typically contain many more layers (up to tens of layers), with layer thicknesses and materials carefully optimized to meet the needs of specific applications.

Performance Advantages of Optical Windows With AR Coating

Optical windows with AR coating offer significant advantages in terms of optical performance. The most direct benefit is the significant increase in light transmission. Taking ordinary optical glass as an example, the reflectivity of each surface is about 4% when not coated, and the total transmittance of both surfaces is about 92%. After coating a high-quality transmittance-enhancing film, the reflectivity of one surface can be reduced to less than 0.5%, and the transmittance of both surfaces can reach more than 99%, which is especially important for energy-sensitive applications (e.g., solar energy systems, laser systems).

The reduction in reflection loss not only improves light transmission, but also brings a series of derived advantages. First, stray light generation is reduced, improving system signal-to-noise ratio and imaging contrast. In imaging systems such as photographic lenses and microscopes, this means clearer, sharper images. Secondly, the risk of ghosting and flare is reduced, which is particularly noticeable in strong light source environments (e.g., backlit photography, laser applications).

Color fidelity is another important advantage. Traditional uncoated optical windows can cause color distortion due to surface reflections, which can lead to differences in the transmittance of different wavelengths of light. High-quality transmittance enhancement films can achieve uniform reflection reduction over a wide spectral range, ensuring balanced transmission of each color component, which is especially beneficial for color imaging, display and other applications that require high color reproduction.

Durability and environmental stability are also important indicators of transmittance enhancement film performance. Modern transmittance enhancement films usually use hard materials (such as metal oxides) as the outer layer, with good mechanical strength and chemical stability, able to resist daily cleaning, friction, and the impact of harsh environments (high humidity, salt spray, etc.). Some specially designed permeation enhancement membranes also have additional features such as hydrophobicity and antifouling, which further extends their service life.

Application areas for AR Coating Optical Windows

Optical Windows coated with AR Coating play a key role in many fields. In the field of photography and videography, high-quality film-enhanced lenses and filters have become standard equipment for professional equipment. It not only improves light intake and makes shooting in low-light environments possible, but also significantly improves image quality and reduces flare and ghosting. Modern smartphone cameras commonly use multilayer transmittance-enhancing film technology, which achieves excellent imaging performance in a limited space.

Display technology is another important application area. From liquid crystal displays to OLED screens, transmittance enhancement films are widely used in components such as protective glass and polarizers. It improves both display brightness (reducing surface reflections) and contrast (reducing ambient light reflections), with significant improvements in sunlight readability. Some high-end displays also use transmittance-enhancing films with composite functions such as anti-fingerprint and anti-glare, enhancing the user experience.

In scientific instruments and measuring equipment, the AR coating windows is even more indispensable. Spectrometers, microscopes, laser systems and other precision optical instruments require high light energy utilization, and the application of the transmittance enhancement film is directly related to the sensitivity of the instrument and measurement accuracy. For example, in a confocal microscope, the reflection loss accumulated at multiple optical interfaces may seriously affect the imaging quality, and the use of high-performance transmittance enhancement film is the key to ensure the performance of the system.

The military and aerospace fields have put forward higher requirements for permeation enhancement film technology. Military optical systems are often faced with complex and changing environmental conditions, the need to increase the permeability of the film to maintain the optical performance at the same time with a harsh environment, radiation protection and other special features. The optical windows of aircraft and spacecraft must not only ensure high light transmittance, but also be able to withstand extreme temperature changes and high-speed particle impact, which drives the continuous innovation of permeable film technology

Optical windows with AR Coating have revolutionized optical performance by precisely controlling the interference effect of light. From the significant increase in transmittance to the effective reduction of reflection loss, from the obvious improvement of imaging quality to the overall optimization of system efficiency, transmittance enhancement film technology has become an indispensable key technology in modern optical systems. With the continuous emergence of new materials, new structures and new processes, the permeation enhancement film window sheet will certainly play a more important role in a wider range of fields, and promote the continuous development of optical technology and related industries.