Sapphire Windows: Applications in Aerospace, Medicine, and Industry

Aug. 19, 2025

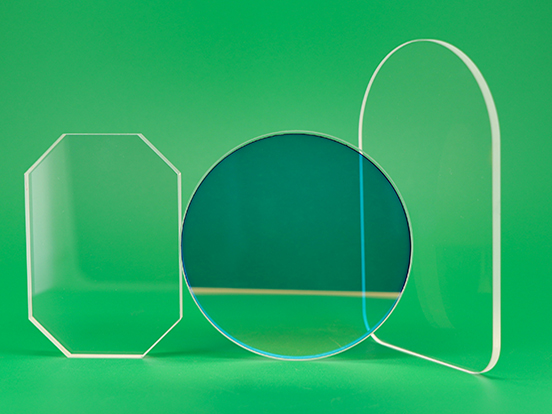

Sapphire windows are renowned for their exceptional durability, hardness, and optical clarity, making them ideal for use in some of the most demanding environments. From medical imaging instruments to aerospace equipment and precision industrial tools, sapphire windows provide superior protection while maintaining high-quality optical performance.

Sapphire Windows in Aerospace and Satellite Equipment

The aerospace industry exposes equipment to some of the harshest environmental conditions, including extreme temperatures, mechanical shocks, and debris impacts. Traditional glass materials may shatter or scratch under such stress, but sapphire remains intact, offering consistent optical quality even in severe conditions.

Sapphire windows are commonly used in satellites and spacecraft to ensure clear, unobstructed views for optical instruments. Their ability to withstand high pressure, wide temperature ranges, and the vacuum of space ensures reliable performance during launches and in orbit.

Additional advantages for aerospace applications include:

Lightweight Design: Sapphire windows can be thinner and lighter than glass alternatives, reducing payload weight—a critical factor in aerospace engineering.

Wide Optical Transmission: Effective across 250 nm to 5000 nm, providing versatility for various optical instruments.

High Mechanical Strength: Tensile strength up to 60,000 psi and compressive strength up to 300,000 psi.

Thermal Endurance: Melting point around 2053°C, operating temperatures up to 1800°C.

Scratch Resistance: Only diamond surpasses sapphire in hardness, providing excellent protection against wear.

Sapphire Optics in Medical Devices

Medical and surgical instruments demand components that are durable and resistant to repeated sterilization and harsh chemical exposure. Sapphire windows excel in these applications due to their resistance to autoclaving, chemical degradation, and scratching.

Applications in medical devices include:

Endoscope Lenses: Provide clear, scratch-resistant imaging for minimally invasive procedures.

Surgical Imaging Windows: Maintain transparency and durability, ensuring consistent performance during repeated use.

Laser-Based Treatments: Sapphire’s high thermal conductivity improves heat dissipation, reducing the risk of overheating during procedures.

Radiolucent Properties: Sapphire does not interfere with X-ray, MRI, or CT scans, making it suitable for inter-operative imaging.

Medical Advantages of Sapphire Windows:

Durability: Withstands repeated sterilization without degradation.

Clarity: Maintains optical transparency for long-term, precise imaging.

Versatility: Suitable for imaging and laser applications due to thermal and chemical resistance.

Industrial and Manufacturing Applications

In industrial environments, sapphire windows allow safe observation of high-temperature and chemically reactive processes. For example, semiconductor fabrication equipment often incorporates sapphire windows in plasma etching systems, diffusion furnaces, and reaction chambers.

Key benefits in industrial use include:

Thermal Stability: Maintains shape and performance under extreme heat.

Chemical Resistance: Unaffected by acids, solvents, or corrosive gases.

Scratch Resistance: Ideal for sensitive optical instruments and high-end consumer devices.

Optical Clarity: Enables precise monitoring of manufacturing processes.

Sapphire windows also find applications in consumer electronics, automotive LIDAR systems, and military optics, where protection against environmental hazards is critical.

Custom Sapphire Window Solutions

Custom sapphire windows can be designed to meet the specific requirements of different industries, whether aerospace, medical, or industrial applications. Factors to consider include:

Required size and thickness for space or weight constraints.

Optical transmission range for specific wavelengths.

Mechanical or thermal stress tolerance for harsh operating conditions.

Surface finish and coatings to optimize performance and durability.

Tailored solutions ensure that sapphire windows provide maximum protection, optical performance, and longevity, even under the most demanding conditions.

Conclusion

Sapphire windows are a premium choice for environments that demand unmatched durability, thermal stability, scratch resistance, and optical clarity. Their applications span aerospace, medical, and industrial fields, offering reliable performance for both everyday use and extreme conditions. By selecting the right specifications and customizations, engineers and procurement professionals can ensure sapphire windows meet the exact needs of their projects, providing high performance and long-lasting reliability.