Optical Vacuum Coating Technology

Jan. 05, 2024

Optical films improve the performance of optical systems and play an important or decisive role in the function of optical instruments. With the rapid development of optical vacuum coating technology, optical thin film began to be colorful in the optical field and has formed an independent technology, that is widely used in a variety of imaging instruments, astronomy, medical care, scientific testing, optical display, and optical communications and other fields.

Optical Thin Film Design

1.1 AR Coating Design

The discovery of transmission-enhancing films in the 1930s contributed to the early development of thin-film optics. Of all the optical films, permeation enhancement films have played the most important role in advancing optical technology. Therefore, the study of the design and preparation technology of permeation-enhancing films is of great significance to the production practice.

-Single layer antireflection coating

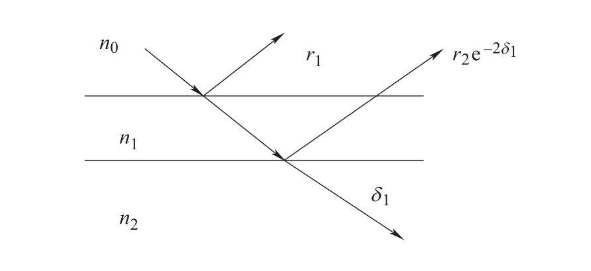

The simplest transmittance-enhancing film is a low refractive index film coated on the surface of the glass, as shown in the figure.

Single-layer AR coating is still widely used today for several simple applications. However, it suffers from two main drawbacks: firstly, the residual reflection is still too high for most applications; in addition, light reflected from the uncoated surface remains neutral in color, while light reflected from the coated surface disrupts the color balance. As a transmittance-enhancing coating in complex lens series such as zoom lenses, ultra-wide-angle lenses, and large relative apertures, it does not meet the requirements.

-Double layer AR coating

For high transmittance requirements transmittance enhancement films, it is difficult to achieve close to 100% transmittance using any kind of substrate as well as common mid-infrared film materials. For double-layer reflectance-reducing films, if the absorption of the film layer is not taken into account, the designed double-layer transmittance-enhancing film can achieve up to 100% transmittance at the reference wavelength.

1.1.2 High reflective film design

Reflective films have an important place in optical thin films. In recent years, with the rapid development of the LED and laser industries, the market demand for highly reflective films has been increasing. It is a common requirement for high-reflective films to have higher reflectivity, smaller absorption, and lower scattering loss. Compared to metal films with higher absorption, dielectric high-reflective films undoubtedly have better optical properties.

For mirrors in optical instruments, the characteristics of pure metal film can already meet the common requirements, in some applications, if the required reflectivity is higher than the value that can be achieved by the metal film, an additional dielectric layer can be added on the metal film to improve their reflectivity, which we can refer to as metal-enhanced high reflective film. To get a higher anti-laser damage threshold of the film, the dielectric-enhanced metal film is difficult to meet the requirements, this is because the absorption rate of the metal film is relatively large, it is easy to be damaged by the high-energy laser, which needs to be plated with a full dielectric high-reflective film, due to the dielectric high-reflective film has the maximum reflectance and the minimum absorption rate, and therefore in the preparation of optical thin film has been widely used.

1.1.3 Design of spectroscopic film

Films or combinations of films with almost constant reflectance in a certain wavelength region can act as neutral beamsplitters. Commonly used are metal beamsplitting films and dielectric beamsplitting films.

Beamsplitters, which are usually always used at an angle, make it easy to separate incident light into two parts: reflected light and transmitted light. If the reflected and transmitted light have different spectral components, such beamsplitters are often called dichroic mirrors.

CLZ Optical Co., Ltd. is a manufacturer who has been manufacturing and trading optical components for many years,We are integrated from design to production to sales. Main products including optical domes, optical filters, optical windows, optical mirrors, optical prisms etc. We also could provide customized service, Utilizes a variety of materials as substrates, such as sapphire, optical glass, fused silica, silicon and so on.

Please contact us free time if you have any needs!