Multi-layer protective coating for infrared optical windows

Aug. 09, 2023

Multilayer Protective Films for Infrared Windows

ZnS, GaAs, and Ge are the three most commonly used window materials in infrared optics, which are characterized by low hardness, high brittleness, and high surface reflection loss, and the method of plating a protective film is usually used in practical applications to improve the environmental adaptability of the window and its optical properties.

In terms of protective films for infrared optics windows, DLC (diamond-like) film is a very excellent infrared protective film, which is widely used on the surface of Ge, Si and other infrared optics windows. However, DLC film cannot be grown directly on ZnS and GaAs windows, and a multilayer film system structure is required. At present, GexC1-x/DLC and BP/DLC protective films are used in large quantities in optical systems such as airplane forward-looking infrared systems in developed countries such as the United Kingdom and the United States.

1. Membrane System Design

Infrared window protection film is a special class of optical reflection reduction film, on the one hand, requires a high optical transmittance, on the other hand, the protective film should have sufficient durability. When designing the IR window protection film, the focus should be on optimizing the mechanical, chemical and optical properties of the film, and at the same time, the feasibility of the film plating process should be considered.

2. Plating and Testing of Membrane Systems

The DLC and BP films of the multilayer infrared protection film were plated by RF-enhanced chemical vapor deposition (CVD), in which the BP film was plated with two gases, PH3 and B2H6, and the DLC was plated with a hydrocarbon gas. Due to the fact that the growth mechanisms of the BP film and the DLC film are not the same, the plating of these two film layers needs to be realized on different CVD platforms. The transmittance of the multilayer infrared protective films was measured by Fourier transform infrared spectroscopy (FTIR) using a Perkin-Elmer Spectrum GX with a resolution of 4 cm-1 and 10 scans, and the surface morphology was measured by Ambios Q-VIS.

The surface morphology of the film layer was observed and analyzed by Ambios Q-View atomic force microscope. The microhardness of the samples was measured using an ORTHOPLAN microhardness tester. The samples were tested in the South China Sea for marine corrosion over a period of 6 months.

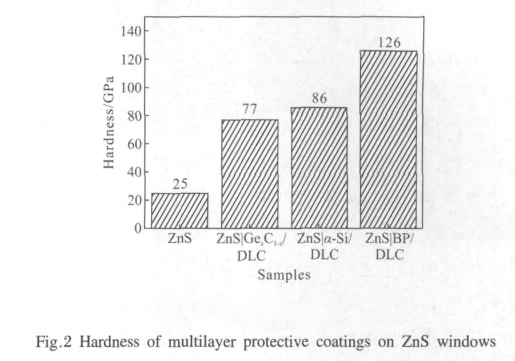

3. Hardness

The figure shows the measured hardness value of the multilayer protective film of the ZnS window infrared window, the hardness value derived from the sample test is the mixed hardness of the multilayer film and the ZnS window, and the hardness of the ZnS-plated multilayer protective film has been increased by 3-5 times. It can be seen that the overall hardness of the ZnS window after plating BP/DLC protective film is comparable to the hardness of monocrystalline silicon, and the BP/DLC protective film has the best scratch resistance.

CLZ Optical Co.,Ltd. can provide you with customized optical windows made of various optical materials, such as N-BK7, H-K9L, B270, Borofloat, silicon (Si), ultraviolet quartz glass, and sapphire. . And can provide a variety of coatings in the ultraviolet (UV), visible light (VIS) or infrared (IR) range.