How to Optimize Optical Windows for High-Power Laser Protection

May. 13, 2025

How to Optimize Optical Windows for High-Power Laser Protection

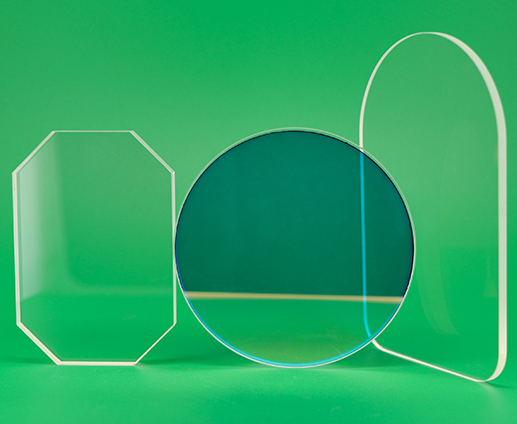

In high-power laser applications, optical components must be engineered for extreme performance and safety. Optical windows, acting as barriers between laser sources and external environments, play a crucial role in protecting both delicate optical systems and human operators. Improperly selected or optimized windows can lead to optical damage, poor transmission, or hazardous reflections. In this article, we’ll explore how to optimize optical windows for high-power laser protection.

Why Optical Windows Matter in High-Power Laser Systems

High-energy lasers pose risks such as:

Thermal damage to optical components

Unwanted back reflections

Reduced beam transmission

Laser-induced contamination

Using the right optimized optical window ensures stable performance, system longevity, and operator safety.

Key Factors to Optimize Optical Windows for Laser Protection

Material Selection

Choose materials with:

Popular materials:

Fused Silica — excellent for UV to IR, high LDT (Laser Damage Threshold)

Sapphire — ideal for extreme durability and scratch resistance

ZnSe — suitable for CO2 laser systems in the IR range

High laser damage thresholds

Broad transmission ranges suitable for your laser’s wavelength

Thermal and mechanical stability

Laser Damage Resistant Coatings

Anti-reflective (AR) coatings enhance transmission, but for high-power lasers, coatings must also resist thermal stress and optical damage. Options include:

Laser-grade AR coatings (optimized for specific wavelengths)

Dual-band coatings for systems using multiple laser lines

Durable hard coatings for harsh industrial environments

Optimal Surface Quality and Flatness

High-power lasers require ultra-smooth, defect-free surfaces to prevent scattering and hot spots:

Surface quality: typically 10-5 or better (MIL-PRF-13830)

Flatness: λ/10 or better to maintain beam focus integrity

Proper Window Thickness

Balance between mechanical strength and minimal optical distortion:

Thickness should be calculated based on:

Laser power density (W/cm²)

Operating environment

System design

Thin windows: lower absorption, better transmission

Thicker windows: higher durability against shock and debris

Protective Edge Treatments

Chamfering, beveling, or AR-coated edges reduce chipping risks and unwanted reflections, improving overall laser safety.

Application Examples

Industrial Laser Cutting and Welding: Fused silica windows with laser-grade AR coatings to handle high thermal loads.

Medical Surgical Lasers: Sapphire windows for scratch resistance and safety in precision procedures.

Research Laser Systems: Ultra-flat, dual-band coated windows for multi-wavelength experiments.

Maintenance and Replacement Tips

Regularly inspect windows for surface contamination or damage.

Replace any window showing signs of burns, scratches, or coating degradation.

Clean using approved optical cleaning protocols to avoid surface defects.

Conclusion

Optimizing optical windows for high-power laser protection involves careful material selection, high-damage-threshold coatings, precision surface specs, and protective design features. Collaborating with an experienced optics manufacturer ensures your windows meet both performance and safety demands, prolonging equipment life and protecting operators in high-risk laser environments.