Development and application of beryllium optical mirrors in optical system

Jun. 16, 2023

◢Optical Mirror, Beryllium

Optical mirrors have an important role in various fields of human development. This paper reviews the properties, processing methods, development status, and latest applications of materials commonly used for beryllium mirrors in optoelectronic systems. Large aperture and long focal length are the development trend of space, ground-based and aerospace optoelectronic systems. The increasing resolution of optoelectronic systems also leads to larger and larger reflector apertures. In order to reduce the mass and improve the performance of optoelectronic systems, the production of large-size mirrors requires that the materials used must be light in mass, high in specific stiffness and dimensional stability, and good in thermal properties. Currently, the materials commonly used for mirrors are beryllium, aluminum, RB-SiC, ULE, and Zerodur, which all meet the requirements of light mass. Among them, beryllium has the lowest density and its modulus of elasticity is 287 GPa, which is second only to RB-SiC, but its specific stiffness is the highest, thus it has the highest resistance to deformation under load, which is beneficial to reduce the mass of the reflector. And the high specific heat and thermal conductivity of beryllium is good for eliminating the temperature gradient in the mirror body of the reflector, so that the reflector can achieve thermal equilibrium faster, which is good for ensuring the good dimensional stability of the reflector. However, the toxicity, brittleness and high price of beryllium limit the application development of beryllium material. Nevertheless, due to a series of excellent mechanical and physical properties, beryllium is still the preferred material for mirrors in space and ground optical systems without other material substitution. And it has been successfully applied in the manufacture of large-diameter mirrors by foreign developed countries, such as cryogenic space telescopes, ground-based astronomical telescopes and other projects.

This paper introduces the properties of commonly used materials for beryllium mirrors in foreign optoelectronic systems, the current status of beryllium mirror substrate preparation, machining and optical processing, and focuses on the application of beryllium and beryllium aluminum alloy in the mirrors and support structures of JWST and F-9120 aerial long-range visible/infrared dual-band reconnaissance cameras.

◢Beryllium optical mirror material

Single-crystalline beryllium is a highly reactive HCP structural metal with a coefficient of thermal expansion 37% higher in the base plane than in the axial plane perpendicular to that plane. The high anisotropy of the coefficient of thermal expansion leads to a decrease in the dimensional stability of the reflector at small temperature changes, making the imaging quality of the optoelectronic system degraded. Therefore, beryllium mirrors and most beryllium material components must be fabricated by powder metallurgy techniques to make the particle orientation as random as possible and to achieve isotropic macroscopic properties. Therefore, to obtain high performance beryllium reflector substrates, it is necessary to start from two aspects: one is the preparation of high quality beryllium powder, and the other is the use of advanced forming and consolidation processes. The chemical composition, physical properties and process performance of beryllium powder will have a significant impact on the consolidation process and the performance of the final product.

The main basis for the classification of beryllium powder for beryllium reflectors is

1. BeO content;

2. whether the mirror blanks are manufactured by the vacuum hot pressing method or the hot isostatic pressing method;

3. the size of the powder particles;

4. whether the powder particles are spherical or other abrasive shapes. These factors determine the dimensional stability and polishability of beryllium mirrors with time and temperature.

Beryllium optical mirror substrate fabrication

After the 1970s, hot isostatic pressing technique was used for the production and research of beryllium mirrors, and became the most common processing method for beryllium mirrors afterwards.

Reflector substrate fabrication is done by using hot isostatic pressing to solidify the beryllium powder out of the mirror blank, and then the mirror blank is machined and ground to the desired shape. This straightforward processing method is not only time consuming, but also results in a significant portion of the blank being wasted, which greatly increases the mirror cost due to the high price of beryllium. For some simple shaped substrates, this method may be more economical, but for most missing and especially complex shaped parts, the efficiency is relatively low. This processing method is suitable for back opening lightweight structure mirror processing, not for honeycomb sandwich structure mirror processing.

In the late 1980s, large and complex lightweight mirror blanks were pressed directly into HIP-NNS by hot isostatic pressing, which offers the advantages of rapid one-step forming, low machining, low cost, and is particularly suitable for the consolidation of expensive, brittle and highly toxic beryllium, a special material that can be processed in honeycomb sandwich structures. The cost of individual beryllium mirrors increases, therefore, the choice of mirror processing method should be based on the number of mirrors processed, mirror structure and processing accuracy.

◢Beryllium optical mirror in space telescope applications

Beryllium has a high coefficient of thermal expansion at room temperature, but has good stability at low temperatures, while beryllium has the advantages of light weight, which makes it is mostly used in the manufacture of reflectors for low-temperature space telescopes.

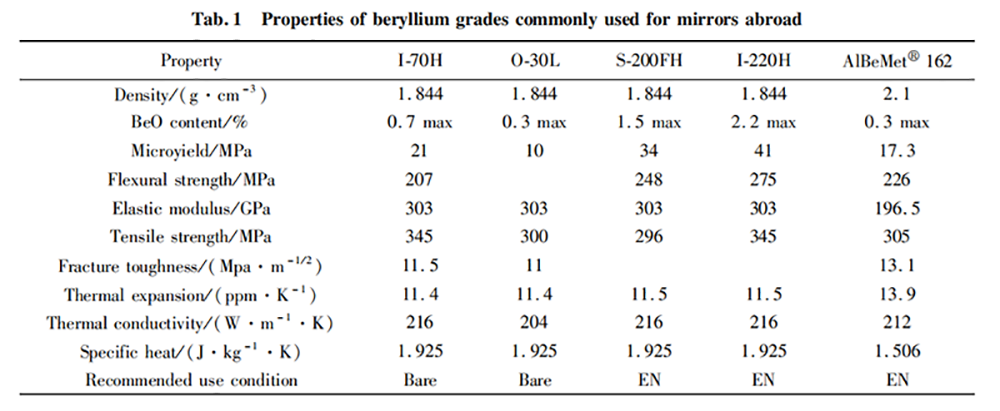

Because of the good stability of beryllium at low temperature, JWST also chooses to use beryllium for the optical support structure of its NIR camera. The candidate materials at the beginning of the optical support structure design are only hot isostatic grade beryllium powder: I-220H, S-200FH, O-30H and I-70H have better isotropy, where S-200FH has relatively low strength and high anisotropy; O-30H has the best isotropy of each, but high cost and low strength, while the optical support structure does not need such high isotropy.

The use environment and requirements of space telescopes have prompted the development of new beryllium materials, and the longer working distance and higher resolution of aerial reconnaissance cameras have put higher requirements on the performance of optoelectronic systems, leading to the application of beryllium aluminum alloy in the reflectors and support structures of aerial long-range reconnaissance cameras. The selection of suitable beryllium material and processing method for specific application environment can ensure that the beryllium reflector meets the requirements for the use of advanced optoelectronic system, while the optical machine support structure can also consider the use of beryllium or beryllium aluminum alloy, and the integrated technology of optical machine support is conducive to improving the performance of optical system and is the development direction of future optical system.

CLZ Optical Co., Ltd. has been manufacturing optical components for many years, and we also provide customized services for our customers. Our main products include optical mirrors, plano-convex lenses, plano-concave lenses, optical spheres, and cylindrical lenses as mentioned in this article.

We use a variety of substrates, such as fused silica, optical glass, sapphire, etc.

Please contact us free time if you are interested in our product!!