Absorption filter vs.Interference filter

Oct. 20, 2025

Optical filters are used to selectively transmit or reject a certain wavelength or series of wavelengths.

There are two working principles of optical filters: one is to use the intrinsic absorption of the material; the other is to use the interference effect of light. Based on the different working principles, optical filters can be divided into two types: absorption filters and interference filters.

I、Absorption filter

It is made by mixing special dyes into resin or glass materials. According to the different ability to absorb light of different wavelengths, it can have a filtering effect. Colored glass filters are the most popular in the market. Their advantages are stability, uniformity, good beam quality, and low manufacturing costs. However, they have the disadvantage of relatively large passbands, usually seldom less than 30nm.

II、Interference filter

It uses a vacuum coating method to coat a layer of optical film with a specific thickness on the surface of the glass. Usually a piece of glass is made up of multiple layers of films, using the interference principle to allow light waves in a specific spectral range to pass through. There are many types of interference filters, and their application fields are also different. Among them, the most commonly used interference filters include bandpass filters, cutoff filters, and dichroic filters.

(i) Bandpass Filters

It can only transmit light of a specific wavelength or narrow band, and cannot transmit light outside the passband.

The main optical indicators of bandpass filters are: center wavelength (CWL) and half bandwidth (FWHM).

According to the bandwidth size, it is divided into: narrow-band filters with bandwidth <30nm;

Those with bandwidth >60nm are broadband filters.

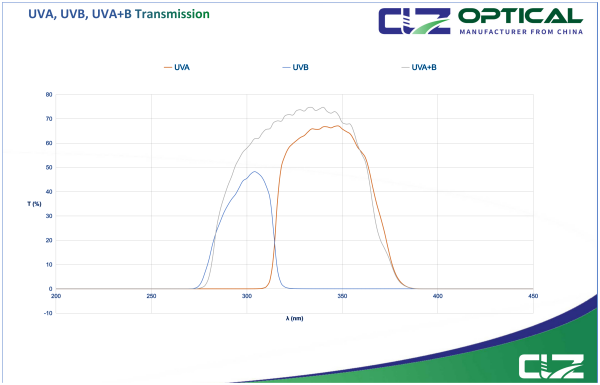

Figure 1, figure 2 show an example of a typical transmission curve for a Bandpass Filter.

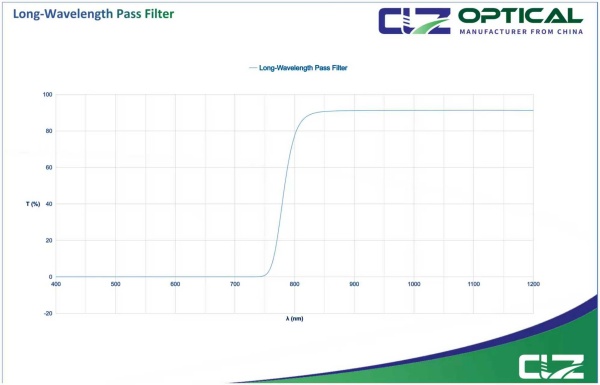

(ii) Cut-off filter

The spectrum can be divided into two areas. The light in one area cannot pass through, which is called the cut-off area, while the light in the other area can fully pass through, which is called the pass-band area. Typical cut-off filters include long-wave pass filters and short-wave pass filters.

Long wave pass filter: refers to a specific wavelength range, the long wave direction is transmitted, and the short wave direction is cut off, which plays the role of isolating short waves.

Short-wave pass filter: A short-wave pass filter refers to a specific wavelength range that transmits the short wave direction and cuts off the long wave direction, which plays the role of isolating long waves.

(iii) Dichroic filter

You can select a small range of colors that you want to pass light through, and reflect other colors as needed.

Cold mirrors and hot mirrors are one type of interference filters, especially dichroic filters. They selectively transmit or reflect light of different wavelengths by coating multiple layers of thin films on a substrate.

The difference between hot mirror and cold mirror in optical filter

Hot and cold mirrors exploit the properties of dielectric coatings to selectively reflect and transmit light of specified wavelengths. Thermal mirrors reflect near infrared (NIR) and infrared (IR) and allow the transmission of ultraviolet (UV) and visible light. Cold mirrors, on the other hand, reflect UV and visible light and allow NIR and IR transmission. Each provides a way to manage and filter light and heat in optical systems, so comparing hot and cold mirrors is important to highlight the applications of each.

Hot mirrors are so named because up to 90% of NIR and IR wavelengths are reflected. They deposit multiple layers of thin-film dielectric coatings on the surface. The material and thickness are chosen to selectively reflect infrared light from the surface while allowing up to 80% of UV and visible light to pass through. Highly transmissive thermal mirrors prevent heat from damaging heat-sensitive components and materials or direct heat to other purposes.

Heat can be directed to the heat sink or away from other components or used for different needs. At the same time, ultraviolet light and visible light pass through the mirror without changing the spectral characteristics. Typically, off-the-shelf thermal reflectors are designed for 0° or 45° angle of incidence.

Although the name "hot mirror" means reflection, hot mirrors can also be used as effective beam splitters and bandpass filters. Heat mirrors are often found in project systems, where the heat generated by high-intensity lamps can be redirected and managed to protect components and prevent the system from overheating.

Cold mirrors are very similar to hot mirrors, except that their dielectric coating is designed to reflect 90% of UV and visible light while allowing 80% of NIR and IR light transmission. Some chilled mirrors are also designed to remove unwanted UV and visible light illumination. It is no coincidence that the reflectivity curve of a cold mirror is similar to the transmittance curve of a hot mirror. This is a feature that makes them hot vs. cold mirrors.

Like hot mirrors, off-the-shelf cold mirrors are designed for either 0° or 45° angle of incidence. They also serve as effective beam splitters and broadband filters. Hot and cold mirrors can be combined in the system as visible bandpass filters to remove UV, NIR and IR from the imaging system.